Ply board sheets help busy buyers keep projects simple and smooth. Trade clients in building and furniture work use them every day. In many markets, these panels act as the first choice when new jobs start. Because of their balance of cost and strength, they fit both small and large orders. Today ROCPLY shares a calm look at this simple yet strong panel.

Why Ply Board Sheets Stay In Demand

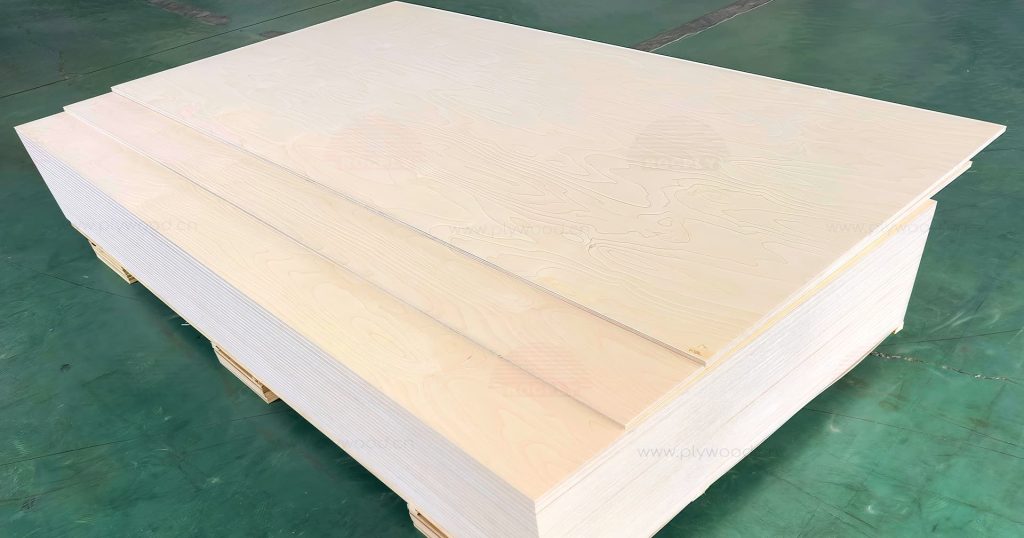

Many wholesalers look for one panel that suits many jobs. They want stock that moves fast and keeps risk low. For this reason, ply board sheets stay at the core of most ranges. Each panel uses cross laid veneers and strong glue lines. Because of this build, the sheet holds screws well and stays firm under load. Contractors trust the panels for wall lining, subfloors, crates and packing. Furniture shops also like the solid feel and clean face. When markets change, demand for these sheets still stays strong. In slow seasons, the same board stock still turns over at a steady pace. During busy times, sales teams can push volume without fear of high claims. This steady flow supports cash plans and keeps storage space working hard.

How ROCPLY 4×8 Plywood Supports Your Business

ROCPLY focuses on real needs from the trade. Our team works with importers, yards and builders in many regions. Together, we build a product mix that keeps shelves tidy and cash flow healthy. ROCPLY 4×8 plywood fits right into these plans. The size stacks well in any warehouse and loads easily in trucks and containers. In addition, full size panels reduce joints on site and cut labour time. Sales teams like the clear spec sheets and stable quality. As a result, they can promise performance with calm and confidence. When buyers ask for plywood sheets for new work, ROCPLY often becomes the first choice. We also help clients match local grade rules and label needs. This support saves time during checks with engineers and site managers. Over time, your brand stands out as the supplier who always brings simple and safe answers.

Types Of Ply Board Sheets For Trade Buyers

Different jobs call for different sheet builds. Some clients need light panels for fast fit outs. Others want dense panels for high load or impact. ROCPLY supplies many types of ply board sheets to suit these cases. You can choose mixed hardwood and softwood cores, or full hardwood cores where strength matters most.

For furniture plywood orders, we can match face grade, sanding level and veneer grain. If you handle outdoor work, we also supply waterproof plywood sheet options with strong glue bonds. In each case, our team checks thickness, moisture and bond strength before loading. We design ranges with clear steps in price and grade. This clarity helps sales teams move clients up or down a line with ease. It also helps buyers hold the right stock mix for local demand. You avoid slow moving items and keep containers filled with proven sellers. Standard thickness ranges from thin backing boards to heavy structural panels. You can cover drawer bottoms, cabinet sides and stair soffits with one family of products. Special machining such as tongue and groove edges or primed faces is also available on request. These options let you match local habits without complex new systems in the plant.

Choosing Ply Board Sheets For Furniture Work

Cabinet makers care about clean lines and calm colours. They also care about edge grip and screw holding. When they pick ply board sheets, they look first at core gaps and face quality. Tight cores support hinges and runners in daily use. Smooth faces save sanding time and reduce putty work. ROCPLY offers panel choices for kitchen boxes, wardrobes, shelves and seat bases. For many buyers, plywood sheets with uniform light faces suit fresh designs. Others prefer warmer grain for classic rooms. Because we control veneer layup, we can align faces to your key lines. We also talk with factories about cutting maps and nesting plans. Simple changes in sheet choice can lift yield from each pack. That gain drops straight into the profit line for each job. At the same time, clean boards reduce dust, noise and rework in the workshop.

Ply Board Sheets For Construction And Site Use

On site, crews need sheets that stand up to rough handling. Forklifts, rain and sun all test the panel. Therefore, construction buyers choose ply board sheets with robust cores and strong glue. Many use them for hoardings, temporary floors and roof decks. Some also use them as backing for waterproofing systems.

ROCPLY panels work with common fixings and site tools. Carpenters cut them cleanly and hit fix marks with ease. The stable core reduces edge crush during transport and stacking. In this way, yards cut losses and keep more sheets in saleable shape. We also offer slip resistant faces for ramps and work platforms. Clear marks on the sheet help crews keep spans and fixing centres within safe limits. With the right advice, clients match panel type to risk level on each part of the build. Site managers also like clear span tables and load notes printed on documents or packs. These guides cut guesswork during layout. Crews waste less time checking with engineers for simple areas. As a result, the whole job flows better, from first sheet drop to final clean up.

Storage, Handling And Cutting Tips For Ply Board Sheets

Good handling habits protect both profit and safety. First, store packs on level bearers in a dry, aired space. Keep water away from open edges, even when you stock waterproof plywood sheet grades. Next, use clean slings and padded forks when you move packs. This step helps prevent edge crush and face marks. In the saw shop, support the sheet fully during cuts. You can also use sharp blades and fine teeth for clean lines. Simple steps like these keep ply board sheets flat, tidy and ready for fast sale. Clear yard rules also reduce damage from short picks and rushed handling. Many of our buyers run quick tool box talks on lifting and stacking. These talks take only minutes yet save many sheets over a full year.

Price, Supply And Stock Planning For Ply Board Sheets

Market prices shift with log supply, glue cost and freight. Smart buyers track these shifts and plan stock with care. Ply board sheets play a key role in this plan. They sell every week, so steady supply matters more than small price moves. ROCPLY shares trend notes on both timber board inputs and shipping lanes. We help buyers set a base order and then top up as sales grow. When clients ask about plywood board price, you can answer with calm data instead of guesswork. This open talk builds trust on both sides. We also support long term tenders for large users. With clear volume plans, we can lock in core raw material and shipping space. That way, your team can sign supply deals with strong backing behind each promise.

Sustainability And Timber Sourcing

More buyers want to know where their panels begin. They ask about forest health, legal harvest and replant rules. ROCPLY works with trusted forest partners and holds key documents on file. Our team checks that cutting rights and land use papers stay in line with local law. We also support chain of custody plans for clients who hold green badges. Clear marks on each pack help your staff link stock to paper trails. This care protects both your brand and your end users. Over time, strong sourcing adds value to each simple sheet in your yard.

Digital Support And Marketing Tools For Dealers

Today trade works both on the ground and online. Because of this, we give dealers simple tools to promote stock. Clients receive photo sets, spec sheets and social media text ready for fast use. Yard teams can post new arrivals and show real loads on the way. Simple posts draw in small builders and furniture shops who watch their feeds. We can also help with banner art and landing page text. When your website highlights core sheet ranges clearly, visits turn into calls. In the end, your sales team spends more time closing deals and less time making basic content.

Quality Checks On Ply Board Sheets Before Shipping

Every pack must arrive ready to work. For that reason, ROCPLY runs strict checks at each stage. Teams record moisture readings, bond strength tests and visual grades for each batch. Staff remove sheets with deep core gaps, wet spots or heavy face defects. Packed units carry clear labels for grade, thickness, glue type and use class. We invite clients to visit our mills and watch these steps in person. Many buyers bring their own test plans and compare results with our team. This open work builds trust and reduces claims after landing. When your client opens a pack, the sheets match the story you shared during the sale.

Common Questions From Wholesalers And Contractors

Many buyers ask how long their sheets can last on site. With good storage and correct use, life stays long. Others ask which thickness suits a job. We guide them through spans, loads and fixing points in simple charts. Some want to know the real gap between ply board sheets and other panel types. We explain the core build and show cut samples from building plywood panels and other boards. Because we run our own mills, we can answer with real facts, not vague sales lines. Clients also ask about formaldehyde levels and glue types. We share test reports and help them meet local rules with ease. Clear answers turn a single trial order into a repeating lane.

Why Global Buyers Trust ROCPLY As A Long Term Partner

Global trade needs more than one good load. It needs repeat orders that arrive on time and match the last batch. ROCPLY treats each order as a long term step, not a quick sale. Our factories monitor moisture, bond strength and surface checks on each pack. Teams in export, quality and logistics stay in close touch with your staff. Together, we solve small issues before they grow. Over time, this steady work turns new trials of ply board sheets into core lines in your yard. Your brand grows with less stress, and your customers enjoy stable stock every season.

As your range expands, we help you add new sizes and grades without heavy risk. This shared planning keeps business calm, even when markets feel busy or uncertain. Many partners started with a single mixed trial load across several thicknesses. We helped them watch feedback from yards, sites and shops. Together, we tuned the mix and improved packing plans for each region. The process felt simple yet had strong impact on stock turn. Today those clients treat ROCPLY as a quiet strength inside their business.

Post time: Dec-22-2025