Birch Wood is Reliable Hardwood for Strong and Clean Builds

Many builders want materials that look clean and perform well. Birch wood meets this need with strong structure and bright grain. It works in modern homes, offices and custom furniture shops. It also gives wholesalers a stable, high-value product line. ROCPLY supports this demand with birch plywood sheets and solid birch timber that stay flat and firm through daily use.

Birch has long served as a trusted hardwood. Its dense fibers give it high strength. Its fine grain creates a smooth surface for clear coats. Craftsmen like its ability to cut crisp edges. Builders like its stable feel. Wholesalers enjoy steady demand for premium projects. These traits make birch a strong choice across many markets.

What Makes Birch Board Stand Out From Other Hardwoods

Many hardwoods serve the building world. Yet birch wood stands apart because it balances beauty, strength and easy workability. The grain stays tight and clean. This helps panels look sharp with natural finishes. Birch also takes paint well. It does not leave rough pores that soak unevenly.

The strength of birch supports heavy loads. Shelves, racks and cabinets all benefit from this stiffness. Builders trust birch plywood sheets to stay straight. This helps doors align well. It helps drawers run smoothly. It helps tabletops stay level. These practical gains matter on real jobs.

Birch responds well to tools. It sands with ease. It shapes with little tear-out and holds screws firmly. These traits give shop teams confidence. They can hit tight deadlines without tricky repairs.

How Birch Panels Helps Your Projects Look Better

Designers pick birch wood for its fresh and clear tone. The color stays light. This brightens small rooms. It also blends well with white walls, stone counters and metal frames. Many modern spaces use birch to create calm and simple interiors.

Birch veneer wood adds visual depth to panels. The grain forms soft waves that look natural. When coated with clear finish, it creates a warm glow. When stained, it gains rich tone without losing detail. This flexibility supports many design styles. Homes, stores and offices all benefit from birch surfaces.

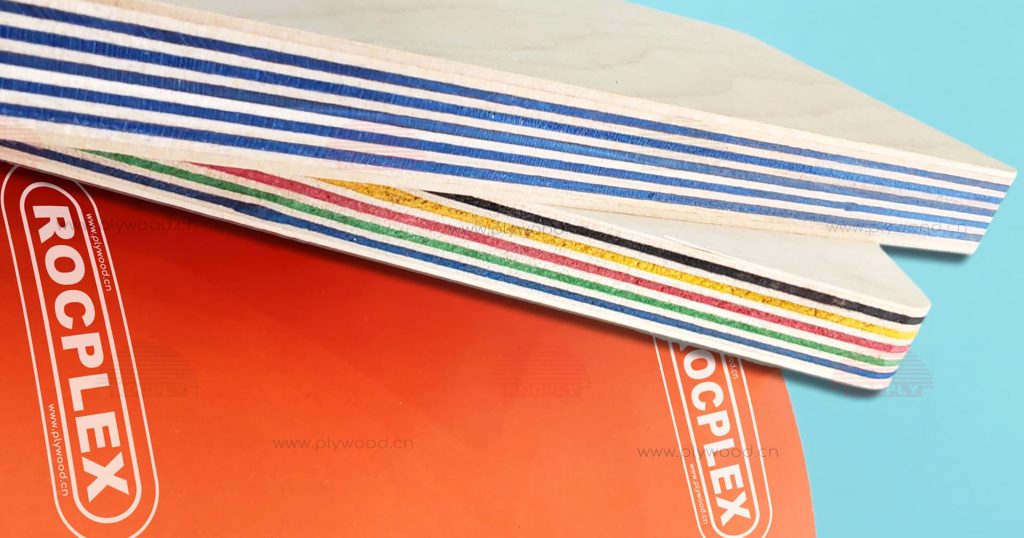

ROCPLY selects veneers with balanced lines. This keeps sheet faces consistent. Wholesalers get packs with clean appearance. Builders get panels that match across full rooms. Designers get predictable results for high-end spaces.

Why ROCPLY Birch Panel Serve Builders and Makers Well

ROCPLY presses birch plywood with tight control. Veneers stay balanced in cross layers. Glue bonds hold firm from edge to edge. Faces sand smooth at the factory. This gives customers clean panels that feel ready for work.

Each sheet stays flat during travel. Edges remain strong even after long routes. Packs stack firmly in warehouses. These steps reduce claims. They also support steady sales for wholesalers.

Builders enjoy birch because it allows precise work. The panels hold fasteners without crush. They cut with straight lines and clean corners. This reduces time spent fixing flaws. It also means fewer failed parts during assembly.

The Role of Birch Plywood Sheets in Furniture and Interior Builds

Furniture makers rely on birch plywood sheets to form cabinets, drawers, shelves and tables. The core stays consistent. The faces look clean. The structure supports daily load without sagging. Many workshops use birch as their main panel for premium items.

Wall panels also benefit from birch. The light tone brightens offices and meeting rooms. It pairs well with warm lights. It also reduces the cold feel of plain drywall. Builders can mount birch wall panels fast. The stable core keeps faces smooth even in large rooms.

Shelving units need strength. Birch handles weight without bending. This keeps books, tools and display items secure. Makers cut wide shelves from hardwood birch panels and trust them to stay firm.

Solid Birch Timber for Strong Frames and Custom Builds

While plywood serves many tasks, solid birch timber holds value in fine work. Solid birch timber supports chair legs, table frames and drawer sides. Its density gives strength to small parts. Its smooth grain creates a clean look under clear coats.

Makers use birch for curved pieces because it bends well with steam. They also turn it into knobs, handles and decorative trims. Many shops choose birch for these detailed tasks because it resists chipping. It also accepts shaping without burning saw edges.

ROCPLY supplies birch in many thicknesses and lengths. This helps wholesalers build sets that suit large and small buyers. Shops can mix sheets and lumber in one load. This reduces freight cost and increases sales options.

Birch Panels in Commercial and Retail Spaces

Commercial spaces need durable surfaces. Birch wood gives a clean look that lasts. It stands up to daily touch. Resists small dents. It stays bright under constant lighting. These traits make it ideal for shops, cafes, clinics and offices.

Retail displays often use birch because it looks neutral. Products stand out against the soft grain. Crews also like birch because it holds screws for shelves and brackets. Store owners change setups often. Birch supports this without damage.

Large corporate spaces use birch panels to soften long hallways. The wood brings warmth while keeping a professional look. It fits both open offices and private rooms.

Comparing Birch Plywood to Maple, Pine and Oak

Buyers often compare birch wood with maple, pine and oak. Each holds different strengths. Birch sits between these choices in density and cost.

Maple feels harder but costs more. Birch offers similar appearance at lower price. It also sands easier than maple. Pine stays light but dents easily. Birch offers far more strength. Oak shows bold grain patterns. Birch looks smoother and calmer. Each market chooses based on style and price.

For many builders, birch offers the best blend. It delivers enough hardness without heavy tools. Gives clean grain without high cost. It works for both high-end and mid-range projects.

Birch Lumber Boards for Custom Furniture and Fit-Outs

Custom makers use birch lumber boards for benches, drawer fronts, trim and table edges. They like birch because it glues well. It stays straight after joinery. It also takes clear finish without blotching.

Edges remain crisp after routing. This helps produce clean shapes in furniture design. Carpenters use birch boards for face frames on cabinets. They cut small parts without breaking fibers.

ROCPLY sorts boards by grade before packing. This gives wholesalers clean stock with predictable color. It also saves time for shops that need many matching pieces.

How Birch Boards Performs in Real Job Conditions

Real projects demand steady performance. Birch wood delivers that. It stays strong under load. Stays flat after fixing. It stays smooth through daily wear. These traits make it easy to trust on site.

Builders see the results fast. Doors align well. Shelves hold weight. Panels stay crisp at edges. Installers use birch in homes and offices with confidence. Many teams report fewer callbacks when using birch. This saves time and helps keep customers satisfied.

Birch also responds well to climate swings. Rooms change between cool and warm air. Shops change between open and closed doors. Birch handles these shifts without warping. This steady behavior protects long-term value.

Birch Veneer Board and Its Role in High-End Design

Fine interiors often use birch veneer wood for its clean look. Veneers add beauty without waste. They also give designers wide visual choice. Smooth lines form across full panels. Light reflects gently on these faces.

Many architects choose birch veneer for meeting rooms and lobbies. The soft tone reduces harsh reflections. The clean grain fits modern design. Veneer also allows large wall sections with uniform color. This keeps spaces balanced and calm.

ROCPLY selects veneers with strict visual standards. Faces remain consistent across each pack. This helps wholesalers supply clean sets for large projects. Builders enjoy faster installs because panels match well.

Why 4×8 Birch Plywood Helps Crews Work Faster

Standard sizes save time. 4×8 birch plywood fits most layouts. Builders cut fewer odd pieces. They waste less material. They also reduce time measuring tricky walls.

Crews can lift 4×8 panels with ease. The sheets slide into place fast. This speed helps complete kitchens, offices and shop displays. Workshops also cut many parts from one panel. This increases productivity.

The 4×8 format also helps wholesalers load containers efficiently. Packs stack tight. They travel safely. They unload cleanly. Yard teams save time during handling.

Birch Plywood in Cabinet Shops and Joinery Workshops

Cabinet makers rely on high-quality materials. Birch wood fits that need. Birch plywood forms strong cabinet boxes. The cores stay stable. The faces take stain or paint with smooth results.

Drawer sides also benefit from birch. The wood handles friction without breaking down. It holds runners firmly. It keeps shape even with daily use. Many shops also use birch to create clear, modern edges on shelving.

Solid birch timber supports many joinery jobs. Makers cut face frames, rails and stiles from birch. They also form doors with birch edges. The wood shapes cleanly without chipping. This reduces waste and rework.

Birch Plywood for Tables, Benches and Heavy Use Areas

Large surfaces need strength. Birch wood offers that through its dense structure. Tabletops feel firm under load. Workbenches stay stable during tool use. Shelving units carry weight without soft spots.

Many commercial cafes and shops choose birch surfaces. They want tables that resist dents and stains. They also want wood that takes finish evenly. Birch performs well in these conditions. With simple cleaning and regular care, birch surfaces keep their fresh look.

Makers also use birch for curved edges on tables. The fibers bend smoothly with controlled pressure. This helps create soft shapes for modern designs.

Birch Plywood and Its Role in Sustainable Building

Sustainability drives many purchasing decisions today. Birch wood supports this goal when sourced from managed forests. These forests track growth, harvest and replant cycles. They help maintain soil health. They support wildlife.

Birch plywood sheets also use thin veneers. This increases wood yield. More material comes from each log. This reduces waste. Production offcuts can fuel industrial boilers. This lowers energy cost.

ROCPLY follows strict guidelines for responsible supply. Wholesalers can share these details with clients. Builders can include this information in project reports. Designers can specify birch with confidence.

How Birch Plywood Supports Innovation in Furniture Design

Designers want creative freedom. Birch wood supports that. It allows sharp edges, curved shapes and clean lines. It also supports new styles that mix wood with metal or glass.

Birch plywood bends well for layered forms. Makers cut thin strips and press them into curved shapes. These parts become chair backs, lamp stands and custom art pieces. The wood maintains strength even after bending.

Solid birch timber also offers balance between hardness and workability. It supports delicate carvings. Works well on CNC machines. It keeps edges clean after routing. This helps designers produce repeatable, high-end results.

Birch Lumber Boards for Structural Details

Detail work needs solid materials. Birch lumber boards deliver the firmness needed for structural parts. Makers use birch for drawer runners, stretchers, rails and support pieces. Its density supports load without cracking.

Wholesalers stock birch boards in many thicknesses. Builders can combine boards and plywood in one project. This gives them freedom to design with balanced structure. Birch boards also allow smooth joinery. Glue bonds hold well. Screws bite deeply.

When shops sand birch, the surface becomes clean and bright. This helps match boards to veneer panels. It also allows consistent finish across full projects.

Birch Board in Acoustic and Theatre Applications

Many acoustic rooms use birch wood for panels. The surface reflects high tones gently. It absorbs some low tones. This balance reduces echo. It also improves clarity for speech and music.

Theatre builders use birch plywood sheets for stage structures. The wood stays stable under strong lights and shifting temperatures. It handles fast set changes well. It also supports heavy props.

Studios use birch for diffusers and wall accents. The material allows creative shapes. It stays clean under regular light. Many sound engineers prefer birch for its warm tone.

Handling and Storing Birch Board in Warehouses

Wholesalers need clear instructions for warehouse care. Birch wood stays strong when handled right. Sheets should rest on level bearers. Packs should stay dry with open sides for airflow.

Forklift drivers should lift from the center. This prevents corner crush. Yard teams should avoid dragging edges on concrete. Good handling protects face veneers. It also reduces waste.

During storage, panels remain stable. Birch plywood resists sag when stacked correctly. This helps maintain stock quality across long seasons. Wholesalers enjoy lower claim rates with simple routines.

Finishing Birch Panel for Long Life

Finishing brings out the best in birch wood. Clear coats show grain detail. Light stains deepen tone while keeping the clean look. Paint spreads smoothly without heavy filler. These traits help builders create consistent results.

Surface prep stays simple. Light sanding gives a fine base. Dust removal keeps coats clean. Birch does not require complex sealing steps. This saves time. It also reduces material cost.

For high-wear areas, two or three clear coats help. The wood stays smooth. It resists minor scratches. With normal care, birch looks fresh for years.

Why Birch Plywood Continues to Grow in Global Demand

Markets shift often. Yet birch wood remains strong across regions. It offers beauty, strength and value. Supports both large projects and small shops. It works in homes, offices and public spaces.

Suppliers prefer birch because of stable availability. Builders choose it because of steady performance. Designers use it because it matches modern style. Makers love it because it supports creativity.

ROCPLY helps partners meet this rising demand with stable production, strict quality control and clear communication. Our birch product line supports wholesalers who want reliable stock and repeat sales.

Birch Wood That Builds Trust Across Every Project

Birch wood delivers strength and style in one material. It supports furniture, walls, ceilings, cabinets and custom designs. It also serves commercial spaces, retail stores and home builders. With ROCPLY, buyers gain birch plywood sheets, solid birch timber and birch veneer wood that stay stable in real conditions.

ROCPLY continues to help partners grow with reliable supply, strong quality and clear support. When you choose ROCPLY birch wood, you choose a material that works hard, looks clean and supports every stage of the building process.

Post time: Dec-15-2025