Veneered Plywood Buyer Guide

January 2026 — ROCPLY expands its veneered plywood program for global trade buyers. The update targets wholesalers, builders, and furniture factories. It focuses on steadier lots, cleaner faces, and safer packing for long routes. Buyers can now match décor looks with practical performance.

ROCPLY makes plywood, timber panels, and export-ready plywood sheets. The team has built a clear goal for 2026. Make sourcing calmer, and make results more repeatable. That means fewer claims, faster installs, and better yield on factory lines.

Veneered plywood demand grows in fit-outs

Interior design has shifted toward real wood texture. At the same time, many projects need stable, large surfaces. Veneered plywood meets both needs in one product. It gives natural grain, yet it behaves like a panel.

Builders often use wall panels in offices and hotels. Retail fit-outs also need fast turnaround. In those spaces, time matters as much as looks. Therefore, buyers want sheets that arrive flat and ready. They also want colour that stays consistent across packs.

Wholesalers see the same trend in orders. Customers ask for a timber look without solid wood movement. They also want panels that can take transport knocks. As a result, demand for veneered plywood keeps rising across markets.

What veneered plywood is and how it is made

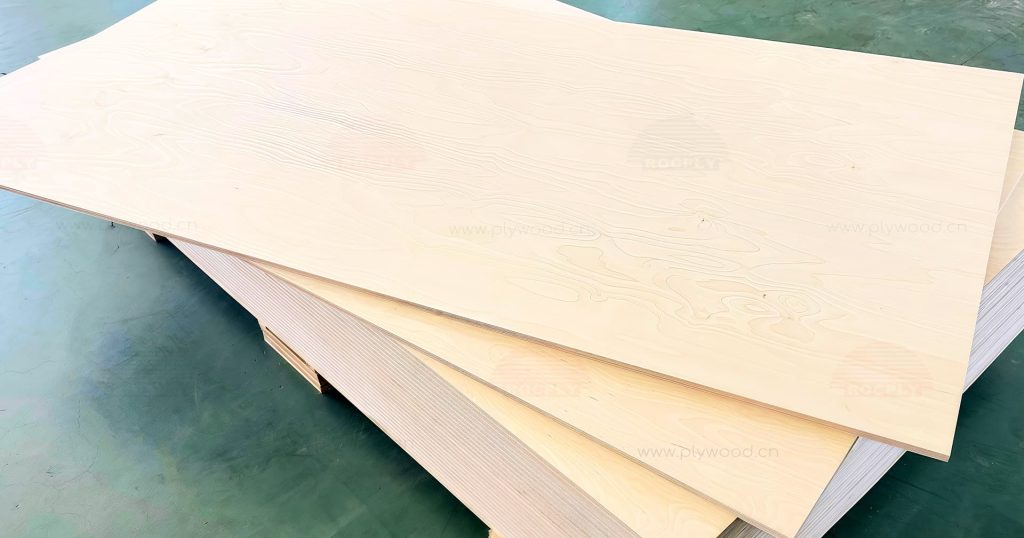

A veneer is a thin slice of real wood. The slice carries grain, colour, and figure. Producers press that veneer onto a stable core panel. With veneered plywood, the core is plywood, not fibreboard.

The plywood core uses cross layers of veneers. Those layers help the sheet resist warp and twist. They also improve strength in both directions. For that reason, the panel suits wide walls and long cabinet parts.

Balance also matters in production. Good mills veneer both sides, or add a balancing back. This step helps the sheet stay calm after finishing. It also limits cupping during storage.

ROCPLY controls veneer moisture before pressing. The team also tracks glue spread and press time. These steps protect bond and reduce bubbles. In addition, the QC team checks sanding and face repairs.

Veneered plywood vs MDF board for cabinets

MDF offers a smooth and even surface. It paints well and routes clean profiles. That makes it popular for doors and trims in dry rooms. However, MDF can swell when water enters the edges.

Veneered plywood brings real timber grain on the face. It also handles bumps better during handling. In many joints, it holds screws more strongly than MDF. This matters for hinges, runners, and frame fixing.

For painted cabinet doors, MDF still has a place. Yet many makers now use veneer for feature ends. They use it for islands, shelves, and open panels. That mix keeps costs controlled and adds warmth.

When you buy plywood for cabinets, ask about core gaps. Ask about thickness tolerance, too. Tight tolerance supports CNC nesting and edge banding. It also keeps door gaps even in final installs.

OSB board vs veneered panels for walls

OSB works well for structural sheathing. It often offers good value in large builds. Many crews use it behind plasterboard or cladding. Still, OSB has a rough, strand face.

That face can look busy in interiors. It also needs more filling for paint. Therefore, OSB fits hidden structure better than décor walls. Veneered plywood, by contrast, arrives with a ready timber look.

Moisture risk also differs by use. OSB edges can swell after wet events. Veneered plywood can also swell at edges, if unsealed. So, sealing and storage matter for both products. A good finish plan reduces risk in either case.

Veneered plywood vs particle board and melamine

Particle board often wins on entry price. Melamine panels add a hard, easy-clean surface. These boards suit low-cost cabinets and shelves in dry zones. Yet the core can chip on edges.

Screw holding can also fail near particle edges. If installers over-tighten screws, the core can strip. Moisture can swell the chips quickly, too. Those issues can drive returns and rework.

Veneered plywood costs more than basic particle board. However, it can reduce damage during transport. It can also lift the look of a finished product. For many showrooms, that upgrade supports higher retail value.

Solid timber vs engineered panels

Solid timber looks premium and feels warm. It also allows deeper sanding during repairs. Yet solid wood moves with seasons and humidity. Wide panels can cup or split across grain.

Engineered panels reduce that movement. In many cases, they keep doors straighter over time. They also keep wall panels flatter across large spans. As a result, many designers use veneers for stability, not only for price.

If you want deep carving, choose solid wood. If you want flat, repeatable panels, choose engineered options. This choice keeps projects predictable and reduces call-backs.

How to specify veneer faces and cores

Clear specifications reduce disputes at arrival. They also help you compare quotes fairly. Start by choosing the face species and decor goal. For example, oak veneer plywood suits light, open spaces. Walnut veneer plywood suits darker, richer interiors.

Face matching and colour control

Colour drift creates the most rework in fit-outs. Set a colour range before you buy. Ask for a control sample and keep it on file. Then match new lots to that reference.

If you need book matched faces, state it in writing. If you need slip matching, state that too. Also define where you accept natural mineral streaks. Clear rules help both sides.

Next, select face grade for the visible side. Higher grades reduce patches and colour variation. Then define the back grade based on use. Hidden backs can accept more repairs, if the panel stays stable.

Core options and stability

Core quality is the next key point. Ask about veneer overlap and gap control. Confirm that the supplier limits core voids. Also confirm moisture targets for your shipping season.

Some buyers choose hardwood plywood cores for higher density. Others choose mixed cores for cost control. Match the core to your machining needs and fastener loads. This choice reduces split edges and broken corners.

Bond and glue choice also matter. Interior panels fit dry rooms and stable climates. Wet-risk areas need better protection and sealing. If the project faces splashes, specify a stronger bond class. Then seal edges during installation.

Finally, set packing rules for your route. Ask for corner guards and flat pallets. Add wrap that blocks spray and dust. Clear labels help warehouse teams track lots.

Finishing and edge details for daily care

Veneer is thin, so sanding needs care. Use fine grit and light pressure. Heavy sanding can cut through the face. Therefore, test your finish on a sample sheet first.

Stains can deepen colour and highlight grain. Clear coats keep a natural look. Paint works too, but it hides the feature. Choose the finish that matches your design goal.

Edges need a plan for a premium result. Many factories use edge banding to match the face. This creates a clean “solid wood” look on shelves. It also protects exposed ply lines from knocks.

For heavy-use counters, add solid lipping strips. This adds impact strength on corners. It also improves long-term repair options. Either method can work with the right process control.

Buying checklist for wholesalers and factories

Trade buyers need a quick checklist for every order. This list reduces risk and speeds approvals. Also, confirm any low-emission target your market expects. First, confirm sheet size and thickness tolerance. Next, confirm face species, grade, and sanding level.

Then confirm moisture range and storage rules. Ask for photos of packs before loading. Check strap tension and corner guards in those photos. Also confirm the pallet base stays flat and clean.

For factories, request stable thickness across the lot. This keeps CNC depths consistent and reduces tool resets. Confirm that the face veneer matches your colour target. If you need book matching, state it in writing.

For wholesalers, plan a simple product ladder. Offer a value face for budget projects. Offer a premium face for feature walls and doors. This range increases close rate and reduces wrong orders.

Veneered plywood FAQs buyers ask

Is veneered plywood real wood

Yes, the face uses real wood veneer. The grain pattern varies like natural timber. That character helps interiors feel warm. At the same time, the core adds stability.

Can veneered plywood handle kitchens and bathrooms

It can work with good sealing and ventilation. Seal cut edges and exposed backs. Avoid standing water and steam blasts. Also, choose a finish designed for wet-risk zones.

Which board paints smoother, MDF or veneer

MDF usually paints smoother with less prep. Veneer can still paint well with primer and sanding. However, paint hides the grain effect. Many buyers choose veneer for clear coats instead.

Does veneered plywood cost more than OSB

Often yes, because veneer adds décor value. OSB usually targets hidden structure and low cost. Still, veneer can reduce finishing labour in décor walls. Total installed cost can be closer than expected.

What causes bubbles and face lifting

Heat, moisture, or poor glue control can cause lifting. Bad storage can also stress the bond. Therefore, buy from mills with clear QC checks. Then store packs flat and dry on site.

Why ROCPLY veneered plywood fits trade programs

ROCPLY builds its veneered plywood for repeat orders. The mill controls moisture at veneer intake. It also monitors press settings every shift. These steps help reduce bow and thickness drift.

ROCPLY also supports private label packing for wholesalers. Clear labels and lot marks speed picking and claims review. Mixed-load planning can also help manage inventory turns. As a result, buyers can run a calmer stock program.

For furniture factories, ROCPLY focuses on stable thickness. The team also checks sanding to protect the veneer face. Clean packing reduces scratches before CNC work. This improves yield and protects delivery dates.

ROCPLY provides a clear specification sheet on request. The team can also share pre-shipment photos. This helps buyers approve lots before loading. It also reduces surprises at arrival.

Common mistakes and quick fixes

Many complaints come from simple site habits. Wet floors and direct sun cause fast bow. So, keep packs off concrete and cover stacks well.

Cut edges absorb moisture faster than faces. Seal edges in wet-risk rooms before installation. In addition, seal sink cut-outs and service holes.

Another issue comes from rushed sanding. Veneer stays thin, so heavy sanding can break through. Use light sanding and test coats on offcuts.

Finally, avoid mixing panels from different lots on one feature wall. Colour can shift across lots. Instead, keep one wall from one lot when possible.

Panel Selection Summary for Practical Builds

Choosing panels feels easier with a simple comparison. Use MDF for smooth painted work in dry rooms. Choose OSB for hidden structure and value-led builds. Pick veneered plywood when you want real grain with stable performance.If you want steady lots and clear packing, consider ROCPLY. Share your face species, grade, and sheet size. Add your target finish and destination port. ROCPLY will respond with a clear offer and lead time.

Plywood

ROCPLY, a trusted name in the construction materials market, is proud to announce the launch of their new line of high-quality ply wood solutions. Designed to meet the diverse needs of the industry, ROCPLY now offers an extensive range of ply options, including structural, birch, marine, and MR plywood.

ROCPLY Plywood Superior Quality and Durability:

ROCPLY ply solutions are meticulously crafted to deliver superior quality and durability. The structural ply offers exceptional strength and stability, making it ideal for applications that require reliable load-bearing capabilities. Birch ply wood, known for its fine grain and consistent thickness, provides versatility and aesthetic appeal. The marine ply wood is specially treated to withstand moisture and weather conditions, making it perfect for marine and outdoor projects. Lastly, the MR ply wood offers moisture resistance, making it suitable for interior applications where protection against humidity is essential.

ROCPLY Plywood Wide Range of Applications:

ROCPLY ply wood products cater to various industries and applications. The structural ply is widely used in commercial and residential construction projects, including flooring, roofing, and formwork. Birch plywood is sought after by architects and designers for its versatility in furniture making, cabinetry, and interior fittings. Marine plywood is a top choice for boat building, docks, and other water-related structures due to its water-resistant properties. MR plywood finds applications in indoor furniture, cabinets, and decorative purposes, offering both functionality and style.

ROCPLY Plywood Commitment to Quality and Sustainability:

ROCPLY is committed to delivering ply wood solutions that not only meet high-quality standards but also adhere to sustainable practices. Their ply is sourced from responsibly managed forests, ensuring a minimal impact on the environment. With ROCPLY’s plywood options, builders and architects can confidently create sustainable and eco-friendly structures without compromising on performance.

We are thrilled to introduce our new line of ply wood solutions. At ROCPLY, we strive to provide our customers with the finest quality materials that meet their specific requirements. With our range of structural, birch, marine, and MR plywood, we aim to empower builders, architects, and craftsmen to bring their visions to life.

For more information about ROCPLY’s plywood solutions and to request samples, please visit [website] or contact [contact details].

About ROCPLY Plywood:

ROCPLY is a leading brand in the construction materials industry, known for delivering high-quality products to wholesalers, builders, and contractors. With a commitment to innovation, sustainability, and customer satisfaction, ROCPLY offers a wide range of construction timber material.

Post time: Feb-02-2026