ROCPLY 12mm plywood sheets

January 2026 — ROCPLY announced an expanded supply program for 12mm plywood sheets for global trade buyers. The program targets steady flatness, cleaner faces, and tighter lot control. It also supports faster packing cycles and clearer labels for warehouse handling.

Demand has shifted in many regions. Builders want one thickness that works across common wall tasks. Furniture plants want repeatable machining for cabinet parts and panels. At the same time, distributors want a fast-moving SKU with fewer returns. Therefore, ROCPLY increased planning for this thickness across several grades and core options.

ROCPLY runs the program with a simple idea. Buyers should get panels that behave the same across repeat orders. To reach that goal, the mill tightened veneer moisture control and layup balance. Moreover, the team strengthened checks for thickness, squareness, and face repairs. These steps reduce disputes and protect project schedules.

ROCPLY announces expanded supply of 12mm plywood sheets

ROCPLY increased output capacity for 12mm plywood sheets to serve mixed-use demand. The company aligns production lots with clear grade rules for trade buyers. Consequently, wholesalers can reorder a matching spec with less risk.

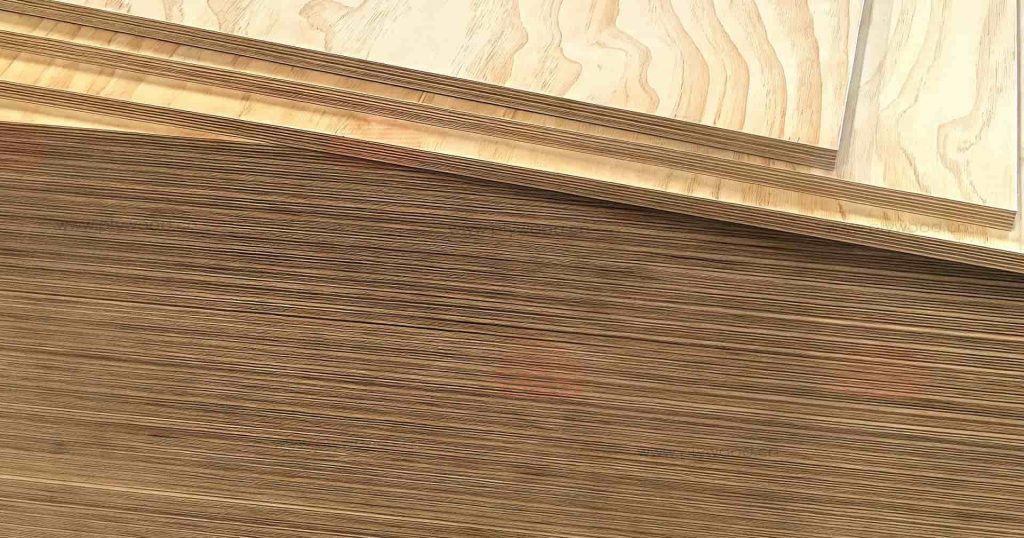

Quality control starts before pressing. Technicians measure veneer moisture and sort sheets by range. Operators build balanced layups to reduce stress inside the panel. Press teams track time, temperature, and pressure for each shift. Finally, inspectors verify thickness and face quality before packing.

ROCPLY also improved export packaging options. Customers can specify stronger corner protectors and moisture barriers. Clear pallet labels support faster picking and easier stock rotation. These logistics upgrades matter for long-distance lanes and multi-handling routes.

Why 12mm plywood sheets fit walls and joinery

Plywood uses thin veneers with alternating grain direction. That cross structure helps the panel stay stable across seasonal humidity changes. It also spreads load across both axes, which helps on studs and frames. Because of that balance, 12mm thickness suits many interior wall uses.

Installers often value edge strength. Plywood edges resist crush better than many fibre boards. As a result, the panel holds up during site handling and fast fixing. Factories also like consistent thickness for CNC programs and hinge recesses. Even small shifts can cause rejects, so control matters.

Still, grade selection decides the finish. A cleaner face grade suits painted or clear-coated wall panels. A utility face works for hidden backing or bracing. Core build also matters for routing and edge machining. A tighter core reduces voids and improves screw bite.

12mm plywood sheets vs 12mm MDF board

12mm MDF board offers a smooth, uniform face. That makes it popular for paint-heavy interior designs. It also routes clean profiles for trims and door parts. Therefore, MDF can reduce surface prep time in dry rooms.

However, MDF handles water poorly. Moisture can swell edges and soften the core. Once swelling occurs, joints often misalign and paint lines crack. So, wet zones and leaky sites raise the risk.

By contrast, 12mm plywood sheets cope better with mixed humidity. Veneers still absorb water, so sealing remains important. Yet plywood often holds shape better after short exposure. In addition, plywood usually grips screws better in edge fixings. That helps installers avoid strip-out during fast work.

Choose MDF for dry interiors with a premium paint finish. Choose plywood for walls that face knocks, fasteners, or changing humidity. Many distributors stock both and sell by use case.

12mm plywood sheets vs 12mm OSB board

12mm OSB board often serves sheathing and subfloor layers. It can deliver strong racking resistance for framed walls. Also, OSB can cost less in large projects, which supports budget builds.

Yet OSB has a textured face that complicates finishing. Even with primer, the strand pattern can show through paint. For that reason, designers often avoid OSB for visible wall panels. Edge swelling can also appear after wet exposure if the edge stays unsealed.

12mm plywood sheets offer a cleaner face in many grades. They also give stronger edge looks for trims and shadow gaps. In addition, plywood sands more evenly, which helps clear coats. Therefore, plywood suits spaces where clients expect a warmer, calmer look.Use OSB for covered structure and budget-led sheathing. Use plywood for joinery, painted walls, and exposed panels. This simple split helps sales teams guide buyers.

12mm plywood sheets vs other wood board options

Particle board and melamine boards win on price in many furniture lines. They also provide a hard, easy-clean surface in cabinet interiors. However, chip-based cores can chip at edges during handling. Fasteners can also lose grip near edges under repeated load.

Solid timber boards deliver a natural look and premium feel. Still, solid wood moves across grain as seasons change. That movement can open joints on wide wall panels. Therefore, many builders prefer engineered panels for large surfaces.

Plywood sits between these options. It offers real wood structure with engineered stability. It also accepts veneer, laminate, and film overlays for many designs. For mixed customers, this flexibility supports broader stock planning.

When structural plywood makes sense

Some wall systems carry more than decoration. Heavy wall cabinets, handrails, and equipment mounts raise demands. In those cases, structural plywood can add confidence for spec-driven work. It can also support bracing roles in framed systems.

Even with rated panels, match grade to exposure. For wet risk, consider WBP plywood bonding and edge sealing. For higher durability needs, marine plywood can suit tough service environments. Still, clear installation practices matter in every case.

When buyers ask for a single panel for multiple jobs, a tiered program helps. Offer a standard wall panel grade for general lining. Then offer a structural grade for load-driven roles. This approach keeps cost aligned with performance.

How to specify 12mm plywood sheets on a purchase order

A clear purchase order prevents most disputes. Start with the application and the target finish. Then add grade, bond class, and permitted face repairs. These details help the mill match your expectations.

Next, confirm tolerance and moisture range. Tight thickness control improves CNC and joinery fit. Good squareness speeds wall installs and reduces trimming. Stable moisture lowers the chance of warp after delivery.

Sheet size and packing also matter. Many buyers use 4×8 plywood sheets for standard cutting plans. Others prefer 2440 x 1220 mm for tender schedules. Either choice works with stable strapping and corner protection.

Finally, request traceable lot marks and clear bundle counts. Those marks support warehouse rotation and quality feedback. They also help buyers link any issue to a specific batch.

Common quality issues and prevention

Trade buyers often see the same defect patterns across suppliers. Warp usually links to uneven moisture or unbalanced layups. To prevent it, confirm moisture range and store sheets flat on arrival. Core voids can show up during routing and edge trimming. For that reason, set a clear core gap limit in your order.

Delamination risk rises when glue control slips. Ask for routine bond checks and clear production records. Also, avoid leaving panels in standing water on site. Face telegraphing can appear under gloss paint. Choose a cleaner face grade and confirm sanding level for that finish.

Thickness variation creates problems in CNC and joinery grooves. Therefore, request a tolerance that fits your tooling. Corner crush often happens in transit, not in production. Stronger corners and tighter strapping cut that damage. Finally, request pre-shipment photos for the first few lots. Those photos help teams align expectations.

Sustainability and documentation buyers request

Many importers now ask for simple, traceable documents. These requests often include origin statements and packing lists. Some tenders also require formal wood legality evidence. Where certification matters, buyers may request FSC or PEFC claims. ROCPLY can support documentation needs based on order scope. Clear paperwork speeds receiving and reduces customs friction.

Handling and installation tips for cleaner walls

Good handling protects even the best panels. Store sheets flat on bearers, not on concrete. Keep stacks away from rain and direct sun. Let sheets rest on site before fixing, especially in humid seasons.

During installation, leave small gaps at joins. Those gaps reduce stress from seasonal movement. Use a consistent fixing pattern and avoid over-driving screws. In wet zones, seal cut edges and penetrations before paint.

For painted panels, use a primer designed for wood. Light sanding between coats improves the finish. For clear coats, test a small area first and adjust sanding steps. These small actions reduce call-backs and protect appearance.

Pricing guide for 12mm plywood price decisions

Buyers often start with the invoice number. However, total cost includes waste, rework, and schedule impact. A low-cost panel can create higher labour cost on site. It can also raise claim costs for wholesalers.

12mm plywood price depends on face grade and core quality. Species choice can shift the cost and the visual tone. Bond type also changes cost, especially for exterior demand. Certification and testing can add value for some tenders.

To compare quotes, align specs first. Confirm grade rules, permitted patches, and sanding level. Then compare packing quality and lead time. Finally, compare the supplier’s consistency across repeat lots. That sequence supports better buying decisions.

People also ask about 12mm plywood sheets

Trade buyers often ask the same practical questions. These answers help teams choose faster and avoid the wrong board.

Q: Are 12mm plywood sheets strong enough for wall panelling? A: Yes, in many interior walls with proper framing. Add blocking behind cabinets and rails. Also, use the right fixing pattern for your stud spacing.

Q: Are 12mm plywood sheets waterproof? A: No wood panel is waterproof without protection. Bond class supports the glue line, not surface sealing. Use sealing, flashing, and good detailing in wet zones.

Q: Which board paints better, MDF or plywood? A: MDF often gives the smoothest paint face in dry rooms. Plywood can paint well with good primer and filler. If humidity swings, plywood often carries less risk.

Q: Is OSB a better value than plywood? A: OSB can suit hidden structure with a covered face. Plywood can suit exposed panels and joinery. Value depends on finish needs and labour time.

Q: What checks matter at receiving? A: Check thickness, squareness, and face grade. Inspect corners for crush damage. Confirm labels and counts before you sign off.

Why wholesalers choose ROCPLY 12mm plywood sheets

ROCPLY designs supply for repeat trade orders. The mill focuses on balanced layups and controlled moisture. It also keeps sanding and grading rules consistent. Those steps support stable yield for factories.

Distributors benefit from clearer packaging and lot marks. These features speed warehouse handling and stock rotation. Construction sites benefit from cleaner faces and tougher edges. That reduces breakage during fast installs.

ROCPLY can also support a tiered program. Buyers can stock a value wall grade and a higher face grade. For demanding tenders, buyers can add rated plywood options. For wet risk, buyers can specify WBP plywood bonding. Where durability sits as a top priority, marine plywood can be discussed.

Closing note for distributors and factories

Choosing wall panels should feel straightforward. Match the board to exposure, finish, and fixing needs. Then lock the spec and buy with repeatability in mind.

For many channels, 12mm plywood sheets offer the most balanced route. They support both site work and factory machining. They also present a calmer path for warranty control.

To request a quotation, share the target application, grade, sheet size, and destination port. ROCPLY will propose an order plan that fits your stock strategy and timeline.

Plywood

ROCPLY, a trusted name in the construction materials market, is proud to announce the launch of their new line of high-quality ply wood solutions. Designed to meet the diverse needs of the industry, ROCPLY now offers an extensive range of ply options, including structural, birch, marine, and MR plywood.

ROCPLY Plywood Superior Quality and Durability:

ROCPLY ply solutions are meticulously crafted to deliver superior quality and durability. The structural ply offers exceptional strength and stability, making it ideal for applications that require reliable load-bearing capabilities. Birch ply wood, known for its fine grain and consistent thickness, provides versatility and aesthetic appeal. The marine ply wood is specially treated to withstand moisture and weather conditions, making it perfect for marine and outdoor projects. Lastly, the MR ply wood offers moisture resistance, making it suitable for interior applications where protection against humidity is essential.

ROCPLY Plywood Wide Range of Applications:

ROCPLY ply wood products cater to various industries and applications. The structural ply is widely used in commercial and residential construction projects, including flooring, roofing, and formwork. Birch plywood is sought after by architects and designers for its versatility in furniture making, cabinetry, and interior fittings. Marine plywood is a top choice for boat building, docks, and other water-related structures due to its water-resistant properties. MR plywood finds applications in indoor furniture, cabinets, and decorative purposes, offering both functionality and style.

ROCPLY Plywood Commitment to Quality and Sustainability:

ROCPLY is committed to delivering ply wood solutions that not only meet high-quality standards but also adhere to sustainable practices. Their ply is sourced from responsibly managed forests, ensuring a minimal impact on the environment. With ROCPLY’s plywood options, builders and architects can confidently create sustainable and eco-friendly structures without compromising on performance.

We are thrilled to introduce our new line of ply wood solutions. At ROCPLY, we strive to provide our customers with the finest quality materials that meet their specific requirements. With our range of structural, birch, marine, and MR plywood, we aim to empower builders, architects, and craftsmen to bring their visions to life.

For more information about ROCPLY’s plywood solutions and to request samples, please visit [website] or contact [contact details].

About ROCPLY Plywood:

ROCPLY is a leading brand in the construction materials industry, known for delivering high-quality products to wholesalers, builders, and contractors. With a commitment to innovation, sustainability, and customer satisfaction, ROCPLY offers a wide range of construction timber material.

Post time: Jan-19-2026