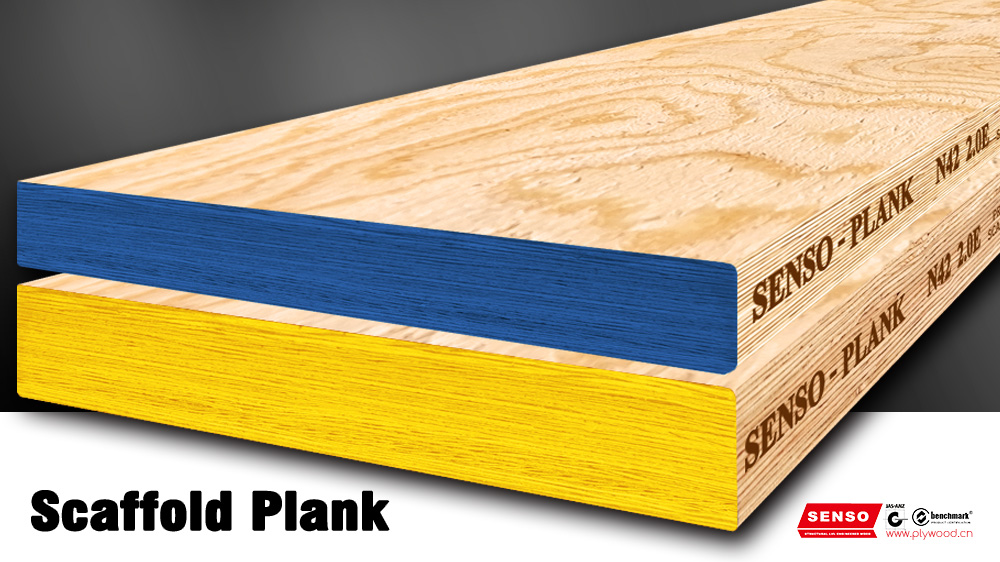

What Is a Scaffold Plank?

A scaffold plank is a core component in temporary working platforms used during construction, repair, or maintenance work. It provides the stable surface workers stand on when using scaffolding systems. Scaffold boards come in various materials—wood, metal, composite—and are designed to support workers, tools, and materials at height. The performance of a scaffold board depends on its material, size, and construction quality. Common terms such as timber boards, walkboards, and scaffolding boards all refer to these load-bearing boards. Selecting the right scaffolding board is critical to maintaining job site safety, improving efficiency, and ensuring compliance with local construction standards.

Scaffold Plank vs. Scaffolding Plank: Is There a Difference?

Though often used interchangeably, scaffold board and scaffolding plank can have subtle differences depending on the region or supplier. Scaffold board is a general term. Scaffolding board sometimes refers to planks pre-designed for specific scaffold frames. Both offer similar support functions, but the design and compatibility may vary slightly.

Choose scaffold boards when looking for general-purpose boards. Select scaffolding boards when working with modular scaffold systems that require precision-fit components.

Scaffold Plank Material Comparison

Timber Planks: Trusted and Traditional

Timber planks are the classic scaffolding boards choice. Used for decades, they offer a natural grip and reliable strength.

Advantages: Cost-effective, easy to cut or replace, good traction.

Best For: Traditional construction, dry environments.

Watch Out: Timber planks can warp or split without proper maintenance.

Wooden Scaffold Plank: Similar, Yet Slightly Different

Wooden scaffold planks usually refer to treated or engineered wood products. These differ slightly from raw timber planks in composition.

Advantages: Pre-treated for moisture resistance, lightweight.

Best For: General-purpose job sites.

Watch Out: Not ideal in environments with repeated wet-dry cycles.

Metal Walkboards: Durable and Uniform

Metal walkboards are gaining popularity due to their consistent performance and long-term durability.

Advantages: Fireproof, rot-resistant, high load capacity.

Best For: High-rise jobs, industrial work zones.

Watch Out: Heavier and costlier than timber options.

Composite Scaffold Boards: The Modern Hybrid

Composite scaffold boards are made from fiberglass, aluminum, or plastic blends. They combine strength and weather resistance.

Advantages: Non-conductive, waterproof, strong.

Best For: Projects near electrical installations, wet environments.

Watch Out: More expensive and less common globally.

Choosing the Right Scaffold Plank Size

Standard Scaffold Plank Sizes

Scaffold plank sizing must align with your scaffold frame and project demands. Common lengths range from 6 to 13 feet, and widths vary between 9 to 12 inches. These standard scaffolding board sizes allow easy compatibility with most scaffolding systems.

Length: Typically 6ft, 8ft, 10ft, or 13ft

Width: Commonly 9in or 10in

Thickness: Varies by region but often 38mm or 50mm

Correct size ensures safety and prevents platform instability. Too short, and gaps appear. Too long, and planks may sag under weight. Standard scaffold boards and scaffolding board types are sized for general use, making them ideal for most construction sites.

Custom Scaffold Plank Sizes

Some projects demand non-standard sizes due to unusual platform spacing or site-specific constraints. Many scaffold plank suppliers offer cutting or manufacturing services to create custom sizes.

Custom sizes provide flexibility but must meet load-bearing regulations. Always confirm load capacity ratings for non-standard scaffold boards. Custom timber planks are especially popular in overseas construction markets.

Load Capacity and Safety Ratings for Scaffold Plank

Understanding Load Classifications

Scaffold plank load capacity is one of the most searched concerns globally. Workers, tools, and materials can quickly exceed unsafe limits without proper planning. Scaffold boards are categorized by load class:

Light Duty: Up to 25 lbs/ft² — best for painters or light trades.

Medium Duty: Up to 50 lbs/ft² — ideal for general construction.

Heavy Duty: 75+ lbs/ft² — suitable for bricklaying, demolition, or large equipment.

Always match scaffold board selection to project load requirements. Timber scaffold boards used on heavy-duty scaffolds should be thick, pressure-tested, and reinforced.

Scaffold Plank Testing and Certification

Trustworthy scaffold planks are tested and certified. Look for the following standards when choosing planks:

OSHA (US): Required for construction use in the United States.

EN 12811 (EU): European standard for scaffolding boards and walkways.

AS/NZS 1577 (Australia/New Zealand): Covers timber scaffold boards and grading.

Scaffold boards with these certifications undergo rigorous inspection for load-bearing strength, moisture resistance, and dimensional stability. Certified scaffolding boards provide long-term safety and assurance on-site.

Environmental Considerations for Scaffold Plank Selection

Weather-Resistant Scaffold Planks

Outdoor construction sites expose scaffold boards to moisture, temperature shifts, and UV rays. Choosing the right plank material helps minimize damage:

Timber Planks: Must be kiln-dried and pressure-treated.

Metal Walkboards: Rust-resistant coatings extend longevity.

Composite Planks: Naturally waterproof and best in wet climates.

Timber planks without proper sealing degrade quickly. Store all scaffold board in dry, covered locations when not in use to prevent warping and mold growth.

Reusability and Lifespan

Durability impacts cost. Wooden scaffold planks may require frequent replacement if mishandled, while metal and composite walkboards last for years. Scaffold board choice should consider both upfront costs and total lifecycle value.

Common Applications of Scaffold Planks

Residential Construction

In home building and renovations, scaffolding plank flexibility and ease of handling are crucial. Timber planks dominate in this space due to cost-effectiveness and lighter weight.

Industrial and Infrastructure

High-rise and infrastructure jobs demand maximum durability. Metal walkboards and heavy duty scaffold boards are preferred, especially in steel-framed scaffolding systems.

Temporary Staging and Events

Scaffold boards are also used in non-construction setups such as event staging. Light-duty timber plank or wooden scaffold planks are often enough for temporary, low-traffic use.

How to Buy the Best Scaffold Plank for Your Project

Key Buying Considerations

When sourcing scaffold planks for wholesale or project use, assess these aspects:

Material Type: Match to your load and environment needs.

Certifications: Look for international compliance standards.

Size Options: Ensure sizes fit your scaffold frame layout.

Supplier Reliability: Work with established manufacturers or distributors.

Durability Features: Treated surfaces, reinforced cores, anti-slip textures.

Tips for Wholesalers and Construction Buyers

Purchase in bulk to reduce per-unit costs.

Request technical data sheets to verify compliance.

Evaluate sample pieces before large-scale orders.

Ensure local regulations are met — scaffold board laws differ per country.

Ask for anti-slip or fire-retardant treatments where required.

Comparing Scaffold Plank Options

Scaffold planks are more than just wooden boards or metal panels. They are essential safety elements on every job site. Choosing the right scaffolding board—whether traditional timber boards, modern composite walkboards, or steel scaffold boards—depends on your specific work environment, project scope, and safety requirements.

Timber Planks: Affordable, practical, and widely used.

Wooden Scaffold Plank: Treated and engineered for added performance.

Metal Walkboards: Built for strength, uniformity, and longevity.

Composite Planks: Ideal for specialty use and extreme conditions.

When in doubt, opt for certified scaffold board that have been tested for load, moisture, and durability. The right scaffold board choice not only protects workers but also ensures smooth operations and long-term project success.

Post time: Jun-02-2025