Ply Board Sheets That Keep Projects Simple

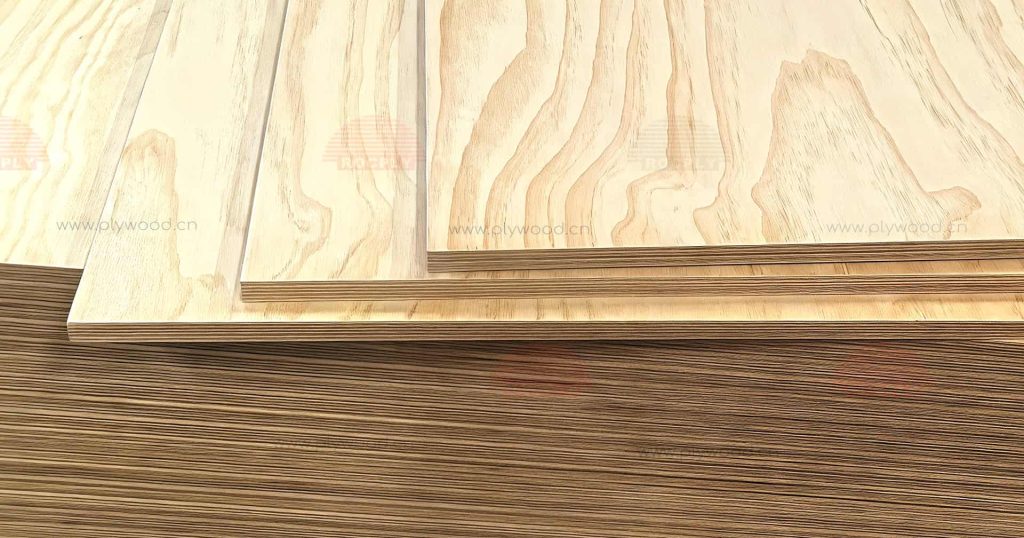

ROCPLY makes sheet timber for people who build for a living. Our ply board sheets support wholesalers, builders and furniture plants across many markets. You can stack them deep in the yard, ship them by container, and still trust the face when you unpack. This press release shares how the right sheet range can keep jobs moving and margins healthy.

Why Ply Board Sheets Matter on Busy Sites

On a real job site, time always runs short. Crews need sheet goods that load fast and suit many tasks. Ply board sheet answer that need with a strong, flat base. Each sheet covers a big area with one simple lift. That means fewer joints, fewer fasteners and less cutting.

Wholesalers also like this format because it stacks well in the yard. Traders move more volume with less handling loss. When stock turns faster, everyone in the chain gains profit. Fast moving stock also lowers the cost of cash tied in the yard. Buyers want sheets that reach site without edge break, core gaps or wet spots. ROCPLY focuses on this basic job site reality. Our team designs sheet ranges that feel safe to walk on, cut and lift each day.

Standard Sizes for Plywood Sheets in 4×8 Format

Across the world, builders treat the 4×8 size as the normal sheet. This format works well for walls, floors and roofs. It rides easily on trucks and slides into tight lifts. Ply board sheets in 4×8 format give clear layout steps on site. Crews can set joist and stud spacing to match the panel size, which cuts waste and saves labour.

ROCPLY focuses on 4×8 plywood because it fits so many designs. Furniture plants also cut many parts from one panel with smart nesting. Standard thickness ranges from light 1/8 inch linings up to stiff 3/4 inch floors. These options let wholesalers match one sheet size with many load levels. Some markets also ask for longer nine or ten foot panels for special jobs. ROCPLY can press those formats when yard demand makes sense. However, most buyers still keep 4×8 as the core stock line.

How ROCPLY Ply Board Sheets Support Wholesalers

Every wholesaler wants steady quality and clear grades. ROCPLY builds ply board sheets with that simple rule in mind. We start with selected veneers and strict bonding lines. Then we press panels under tight heat and pressure control. After pressing, each plywood board passes thickness and moisture checks. Our team trims and sands panels for a clean edge and face. This flow means fewer claims and returns for our partners. When stock stays stable in the rack, buyers come back with repeat orders.

Stable supply matters as much as the sheet itself. ROCPLY plans production runs around your shipment calendar. Mixed thickness packs help fill containers without wasted space. Clear bundle labels show size, grade, glue type and count. That detail shortens unloading checks and warehouse scanning. Many partners also ask for custom branding on edge marks and stickers. We support those plans so your own name stands beside ours in each yard.

Types of Timber and Cores Behind Each Sheet

Good sheet stock starts with the right timber. We match core and face species to the duty needed. Radiata pine gives a light and easy-to-nail core. Eucalyptus or other hardwood adds extra stiffness and load strength. Some lines use mixed cores to balance weight and price. Timber plywood can also include special overlays for film faced or primed use. ROCPLY adjusts glue systems and layups to suit local climates, so panels stay flat in dry heat, damp air or coastal sites.

Cross laid veneers spread loads across the whole panel. That layout lets thinner faces work with a strong core. Glue lines use phenolic or MDI systems for wet or structural grades. Exterior panels suit decks, truck floors and exposed walls. Interior grades stay light and easy to machine for factory use. Compared with OSB, our timber plywood keeps a cleaner edge after cutting. It also takes screws close to the edge with less breakout.

Choosing Ply Board Sheets for Furniture and Fit-outs

Joiners and shopfitters use ply board sheets every day. They cut cabinet sides, shelves and wardrobe cases from clean panels. For visible faces, many choose a smoother grade with fewer knots. ROCPLY offers options that sand well and take paint or clear coats. For carcass work, wood board panels with sound cores give great value. Builders of tiny homes and vans also rely on light but strong panels. They need stock that takes screws without split edges. Our sheets meet that need across many thickness ranges.

Many designers now show plywood edges as a feature, not a flaw. Clean cores and tight glue lines make that look possible. ROCPLY fine tunes pressing cycles to reduce gaps and overlaps. That means less filler work for your shop team. When a project needs a stable carcass, many makers reach for ply board sheets from ROCPLY. They know the panels stay square after transport, cutting and fixing. That reliability keeps install crews on schedule and within budget.

Ply Board Sheets vs Solid Timber and Other Panels

Many buyers ask when to pick ply over solid wood. Ply board sheets give more stability than wide solid boards. Cross grain layers reduce warp and twist over time. Compared with particle board, plywood resists edge damage far better. It holds screws more firmly and copes with job site bumps. Wooden board sheets also weigh less than many MDF grades. That helps site teams lift and fix panels by hand. For many uses, 4×8 plywood beats other sheet goods on value and lifespan.

Solid timber still has a place in fine joinery and visible framing. Yet wide boards move more with humidity swings. Sheet products spread that movement across many thin plies. MDF brings a very smooth paint face but adds extra weight. Particle board offers sharp pricing but drops strength and screw holding. Plywood sits between these options on both price and performance. For many trade buyers, that balance keeps orders flowing toward plywood board stock.

Handling, Storage and Cutting Tips for Ply Board Sheets

Good handling keeps sheets in sale-ready shape. Yard teams should keep ply board sheets on level bearers. Stickers between packs allow air to move and avoid stain. Cover stacks from rain, yet leave the sides open for airflow. On site, crews cut panels on stable trestles or tables. Straight saw guides keep edges true and clean. Sharp blades stop tear out on face veneers. After cutting, workers seal raw edges where moisture may attack. Simple habits like these extend service life for every panel.

Forklift tines should stay level to avoid corner crush. Drivers need clear guides painted on the warehouse floor. Simple marks show safe turning circles around sheet stacks. On trucks, teams strap packs with edge protectors under the belts. That step spreads pressure and shields face veneers. Site crews also use lift plans for upper floor deliveries. Good planning reduces rush moves that risk damage and injury.

Quality Checks Wholesalers Can Use on Every Sheet

Simple checks protect your brand and ours. Staff can sight down sheet edges to spot warp or bow. They can tap faces to hear hollow spots that suggest voids. Calipers confirm that thickness meets the spec on paperwork. Moisture meters help confirm the stock suits local climate zones. Traders can also test screw holding near the edges. Good ply holds firm without splits or crush. These quick steps give buyers trust in your warehouse stock. Trusted stock keeps your sales pipeline strong and stable.

Face checks also reveal sanding quality. Light across the surface should show even texture without ridges or swirl marks. Staff can test panel stiffness by setting sheets across known spans. A simple deflection check gives a feel for grade strength. For large accounts, ROCPLY can share formal test reports and span tables. That data helps your sales team answer engineer questions with confidence.

Questions Buyers Often Ask About Ply Board Sheets

Many search terms around ply board sheets match real voice questions from buyers. They want clear, short answers from suppliers.

What is the standard size of a sheet?

Most buyers expect 4×8 feet, which covers about 1.2 by 2.4 metres.

Which thickness should I keep in stock?

For walls and linings, many yards carry 9 to 12 millimetre panels. For floors and heavy racks, 18 millimetre sheet often works best.

Can one sheet type suit both furniture and construction?

In many cases a versatile structural panel covers both needs. Your ROCPLY contact can match grade and glue to your key customers.

How many sheets fit in a container?

The answer depends on thickness and packing, yet we help you plan the mix. Our team shares loading diagrams for common 20 foot and 40 foot loads.

How does plywood compare with MDF or particle board?

Plywood sheet beats these boards on screw holding and edge strength, while keeping weight under control.

Sustainable Sheet Timber for Today’s Projects

Many buyers now ask where their wood comes from. Ply board sheets from certified timber give a clear answer. ROCPLY works with forests that follow strict chain of custody rules. Responsible harvest plans protect soil, water and wildlife. Efficient pressing lines also cut waste and power use. Thin veneers use more of each log than sawn boards.

Many specifiers now list low emission glue lines as a must have. ROCPLY offers options that meet strict indoor air rules. Efficient dryers and presses also trim energy use per panel. Offcut pieces feed into biomass systems instead of landfill. These choices give wholesalers a clear story for tender documents. When clients ask about carbon and impact, you can answer with facts, not guesswork.

Why ROCPLY 4×8 Plywood Works as Your Go-To Sheet

ROCPLY 4×8 plywood sits at the heart of our range. These panels line walls, floors, decks and crate sides worldwide. We tune glue systems for exterior, structural and interior needs. That gives wholesalers one brand for many stock codes. Ply board sheets under the ROCPLY name carry clear marks and labels. Buyers see grades, sizes and standards at a glance. Support teams answer technical questions on spans and loads. When your warehouse stands behind one reliable sheet brand, quotes become simple. Our customers get fast answers and strong panels on every truck.

Digital tools also support the physical stock. We share photos, packing lists and spec sheets before each load ships. That detail lets your team prepare sales campaigns ahead of arrival. Many partners build online catalogues that feature ROCPLY 4×8 plywood as a hero product. Clear product pages help end users pick the right panel the first time.

For importers and distributors, the next step stays simpl

e. Share your key thickness list, target grades and port. ROCPLY will map a sheet program that fits your lanes and your customers. With reliable plywood on every ship, you can focus on service, not supply problems.

Post time: Dec-22-2025