What Are I Beam Joists?

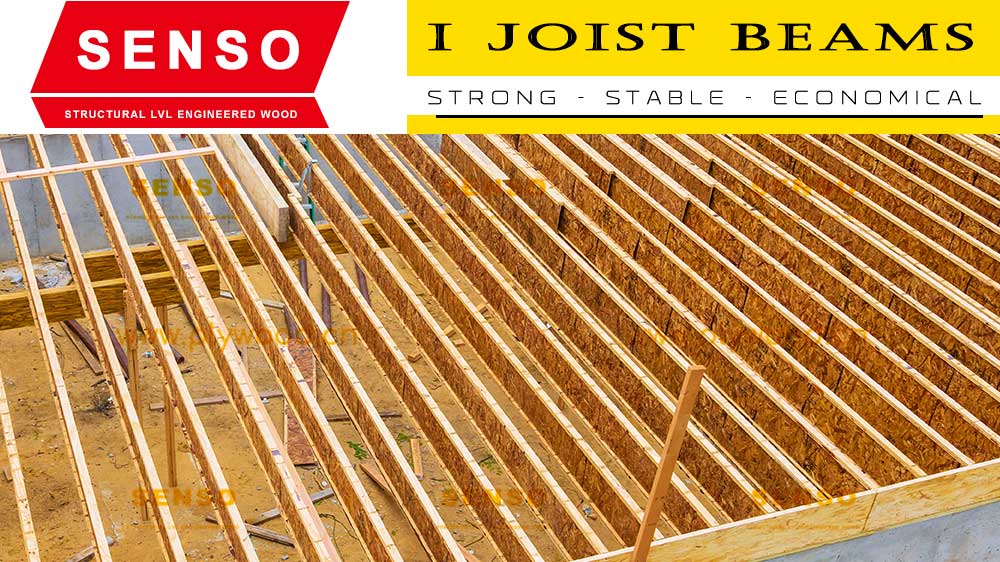

I beam joists are structural framing components made from engineered wood. Their name comes from their shape — resembling the capital letter “I” — which offers maximum bending resistance with minimal material use. The top and bottom sections (flanges) are usually made from LVL (laminated veneer lumber), while the vertical section (web) is made from oriented strand board (OSB). This configuration delivers high stiffness and consistent shape, making I beam joists ideal for floors and roofs. Unlike traditional timber beams, I beam joists maintain straightness and uniformity throughout their lifetime, even in demanding environments.

For a comprehensive overview of engineered wood I-beam systems and their common applications, check out APA I-Joist product guide .

Why I Beam Joists Are Replacing Traditional Wood

Performance and Strength

Traditional wood is vulnerable to knots, moisture shifts, and splitting. SENSO I beam joists, however, are engineered for uniform strength. Every joist meets or exceeds key load-bearing standards — no weak spots, no surprises.

Dimensional Stability

Wood moves with the seasons. It swells, twists, and shrinks. SENSO I beam joists remain stable. Their layered LVL flanges and OSB webs keep dimensions accurate year-round.

Longer Spans

One of the biggest reasons contractors switch to engineered i joists is their ability to span longer distances without intermediate supports. This allows open floor plans, fewer support columns, and creative architectural freedom.

Less Material Waste

Traditional lumber often needs trimming and discarding due to defects. SENSO joists are precision-cut, with fewer waste pieces and more usable length. You save money and material.

SENSO I Beam Joists in Real-World Applications

Residential Buildings

From suburban homes to multi-story villas, SENSO structural I joists create sound floors that don’t squeak or sag. Builders appreciate faster framing and reduced callbacks.

Commercial Projects

Office towers, retail spaces, and educational facilities use engineered wood floor joists to cover wide floor plates without bulky steel or excessive supports.

Modular and Prefab

Factory-built homes and prefab units need materials that are exact. SENSO I beam joists arrive ready to drop in with minimal on-site modification.

Public Infrastructure

Fire stations, hospitals, and schools choose SENSO for strength and durability. Structural i joists improve acoustic performance, which helps in noise-sensitive environments. For details on how I-beam joists are rated for load capacity and their design performance, see the APA performance-rated I-Joists (PRI) .

I Beam Joists Technical Performance Breakdown

| Property | Value |

| Flange Material | Laminated Veneer Lumber (LVL) |

| Web Material | OSB (Oriented Strand Board) |

| Standard Depths | 200mm – 400mm |

| Max Length | Up to 12m |

| Bending Strength | ≥ 39 MPa |

| Modulus of Elasticity | ≥ 11,000 MPa |

| Fire-Resistant Option | Available |

| Drilling Zones | Pre-marked, safe-to-cut zones |

All data is based on EN, AS/NZS, or ASTM-certified testing.

Common Buyer Questions Answered

Can SENSO I beam joists be used with radiant floor heating?

Yes. The OSB web and LVL flanges can accommodate heating channels and remain dimensionally stable during temperature shifts.

What’s the fire rating of these joist?

SENSO offers standard joists and fire-rated versions compliant with multiple international fire safety standards.

Is special training required to install them?

No. Any builder familiar with timber framing can install SENSO joists. We also offer online guides and support.

Can I beam joists be used with steel framing?

Yes. SENSO joists integrate well with hybrid framing systems. Custom connection hardware is available.

Global Use Cases of SENSO I Beam Joists

Australia, builders use SENSO joists for bushfire-resilient homes and cost-efficient modular classrooms.

Europe, passive house builders rely on our joists for airtight, high-R-value floors that match their insulation goals.

USA, SENSO I joists compete head-to-head with APA-rated brands, delivering superior moisture resistance and competitive pricing.

Africa and the Middle East, developers rely on lightweight wood I beam options due to limited crane access or expensive steel.

Comparing to Glulam, Trusses, and Metal Joists

Vs. Glulam Beams

Glulam is heavier and better for load-bearing columns or exposed design. But for floor joists, SENSO I beam joists are lighter, easier to transport, and quicker to install.

Vs. Open-Web Trusses

Open-web steel trusses provide service space but are bulky and hard to stack. I joists fit in tighter shipments, saving freight cost.

Vs. Metal Joists

Metal joists are strong but conduct heat and require more insulation. Wood-based I joists offer better acoustic and thermal properties.

Shipping, Packaging, and Global Supply Efficiency

Smart Packaging for Every Shipment

SENSO packages I beam joists with durability in mind. Each bundle is strapped, shrink-wrapped, and clearly labeled with specifications. Whether shipping locally or across oceans, products arrive intact and ready for immediate use.

Global Distribution Network

We ship directly from major ports in China and Southeast Asia. Orders are fulfilled through FCL (full container load) or LCL (less than container load) depending on volume.

Our logistics partners provide fast customs clearance, and our English-speaking documentation team ensures zero delay on paperwork.

Volume Discounts and Container Optimization

Buyers who order in bulk benefit from reduced unit pricing and container optimization strategies. We help you maximize your profit margins without sacrificing product quality.

Sustainability and Eco Certifications

I Beam Joist Built with Responsibility

SENSO I beam joists are made with PEFC- or FSC-certified timber sources. We use fast-growing plantation wood to reduce forest impact. The OSB baord and LVL timber used in every joist are bonded with eco-friendly adhesives that meet E0 or E1 emission standards. To learn more about the sustainability of timber and the importance of FSC chain-of-custody certification, visit FSC chain-of-custody certification .

Lower Carbon Footprint

Compared to steel or concrete framing systems, wood I beam products have significantly lower embodied carbon. Choosing SENSO supports both green building credits and long-term environmental goals.

LEED and BREEAM Compatibility

SENSO joists qualify for points under LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) frameworks. Builders looking to meet sustainability benchmarks can rely on our certified supply chain.

Tips from Contractors Using SENSO I Beam Joists

Pre-Layout Saves Time:

Mark joist centers on sills before placing beams. This small prep step speeds up alignment.

Use Web-Stiffeners Where Required:

For point loads and bearing walls, add SENSO-approved web stiffeners. It takes minutes and improves long-term performance.

Store Flat and Dry:

Though engineered for stability, always store bundles flat and off-ground. Avoid long-term UV exposure before install.

Trust the Span Tables:

SENSO tables are conservative but accurate. Our engineers validate every value through in-house and third-party testing.

Leverage Our Technical Team:

Stuck on a layout? Need fire detail clarification? Contact SENSO’s support team – fast response, practical advice.

Real Customer Feedback on I Beam Joists

“We switched to SENSO I beam joists two years ago and haven’t looked back. Straighter, faster to install, and our crews love them.”

— Dan M., Site Supervisor, Brisbane, Australia

“For multifamily framing, SENSO’s I joists save us days. No callbacks due to sagging floors, even after months.”

— Angela T., Project Engineer, Houston, USA

“Their packaging and delivery timing are top-notch. As a supplier, I need that kind of consistency.”

— Michael Y., Building Materials Wholesaler, Auckland, NZ

“It’s rare to find a company with both technical depth and excellent customer service. SENSO checks both boxes.”

— Emil R., Architect, Munich, Germany

I Beam Joists Certifications and Compliance

APA PR-L290 Certification (North America)

EN 14250 / EN 1995 Compliance (Europe)

AS/NZS 4357 / 2269 Standards (Australia & NZ) For detailed Australian building code compliance on timber framing and engineered wood products, refer to the National Construction Code (NCC) for Timber Framing .

CE & FSC Chain-of-Custody

Customs Declaration & Third-Party Inspection Available

Builders, engineers, and inspectors can trust that SENSO I beam joists meet international safety, strength, and durability expectations.

How to Order SENSO I Beam Joists

Contact Our Sales Team

Reach out via email, phone, or WhatsApp. We respond within one business day.

Send Specifications

Let us know your required dimensions, quantities, and destination port.

Get a Fast Quote

We offer CIF, FOB, or EXW pricing. Logistics support and documentation are included.

Approve and Ship

Once confirmed, production starts within 5–7 days. We ship globally with tracking updates provided.

Why Choose SENSO for I Beam Joists

- Decades of engineered wood experience

- Professional technical support and documentation

- Full range of sizes and custom production

- Competitive pricing with stable supply

- Strong track record with builders in 30+ countries

SENSO combines world-class manufacturing with responsive service. Every I beam joist carries our commitment to precision, durability, and innovation.

SENSO I-Joist Beams

SENSO I Joist, a breakthrough in modern construction. Engineered for strength and flexibility, these timber joists are revolutionizing floor and roof framing. Lightweight yet robust, SENSO I Joists blend sustainability with performance, offering a cost-effective solution for builders and architects. Learn how I Joists are setting new benchmarks in building technology.

Post time: May-26-2025