Grooved Plywood Wall Panels for Interior Wall Cladding | ROCPLY

ROCPLY Grooved Plywood Wall Panels

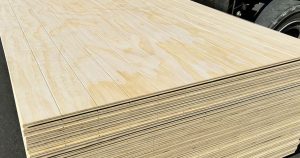

Grooved plywood wall panels provide a structured interior wall solution that combines visual definition with stable material performance. Designers and builders use these panels to introduce clean lines, controlled shadow effects, and consistent surface rhythm across interior wall cladding. As a result, interior spaces gain both architectural character and long-term reliability.

ROCPLY® develops grooved plywood panels by machining precise groove profiles directly into engineered plywood sheets. This integrated approach reduces the need for additional surface treatments while maintaining the strength and dimensional stability of plywood construction. Therefore, installers can achieve uniform results across large wall areas with fewer installation steps.

What Are Grooved Plywood Wall Panels?

Grooved plywood wall panels are interior wall panels that feature linear grooves cut into the face of plywood sheets. These grooves may run vertically, horizontally, or follow specific layout patterns depending on design intent. Because the grooves form part of the panel surface, the panels retain their structural integrity while delivering enhanced visual depth.

In contrast to surface-applied decorative systems, grooved plywood panels integrate appearance and structure into one material. As a result, they support predictable installation and consistent performance in residential and commercial interiors.

Interior Applications of Grooved Plywood Wall Panels

Residential Interiors

Homeowners and designers frequently use grooved plywood wall panels in living rooms, stairwells, bedrooms, and hallways. The grooves add texture without overwhelming the space. Moreover, plywood construction helps panels remain stable under normal indoor climate changes.

Commercial and Public Spaces

In offices, retail stores, hotels, and public buildings, grooved plywood panels help define zones and guide visual flow. Because these panels offer strong fixing performance, they suit high-traffic areas where durability matters. Therefore, many commercial interiors rely on grooved plywood panels for long-term wall finishes.

Feature Walls and Accent Areas

Designers often specify grooved plywood wall panels as feature surfaces. In addition, combining groove layouts with lighting enhances shadow contrast and architectural depth. This approach creates focal points without complex construction methods.

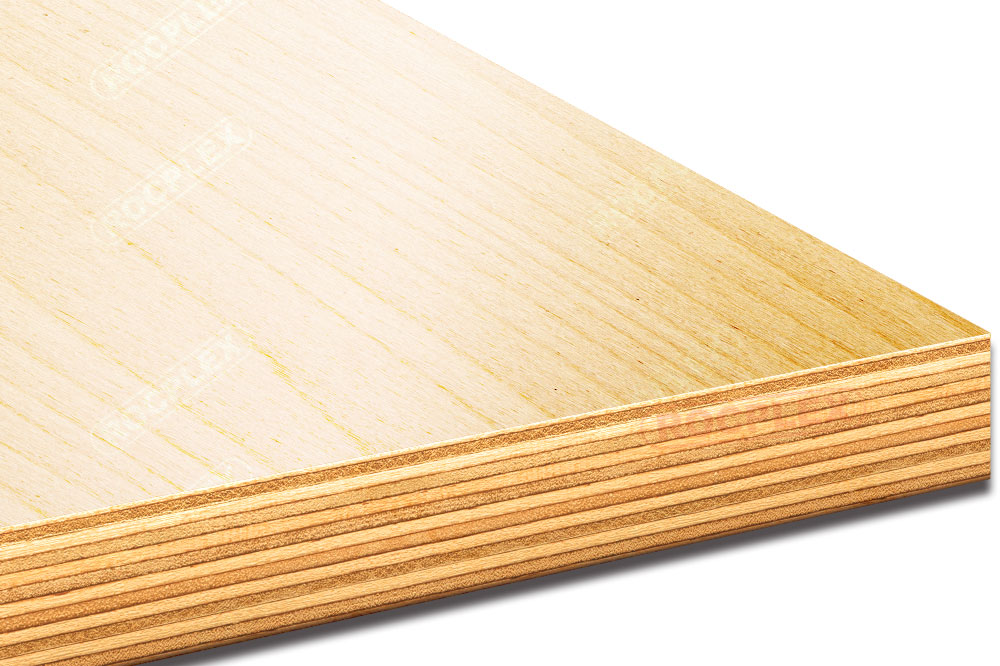

Grooved Plywood Panel Options and Series

ROCPLY supplies multiple grooved panel options based on groove spacing, depth, and orientation. Narrow grooves create subtle texture for refined interiors, while wider grooves deliver bold visual rhythm. Furthermore, vertical or horizontal layouts allow designers to control perceived room height and width.

For decorative-focused designs, you may also explore our decorative panel wall finishes to review visually driven groove layouts.

Grooved Panel Series

Appearance Grades for Grooved Plywood Wall Panels

ROCPLY offers multiple appearance grades to match different design goals and budgets. Each grade controls surface consistency, wood grain character, and natural visual features.

Higher appearance grades suit exposed interior walls where visual balance matters most. Meanwhile, standard grades support cost-effective wall coverage in general interior spaces. In all cases, controlled veneer selection helps maintain consistent quality within each grade range.

All appearance grades are produced with controlled face selection to ensure stable quality within each grade classification.

ROCPLY supplies several grooved panel series based on groove shape, spacing, and layout direction. Each series supports a specific interior style while keeping installation simple.

For example, linear groove layouts suit modern interiors. Wider groove spacing creates bold visual rhythm. Vertical or horizontal orientations also help designers control wall proportion. In addition, custom groove patterns can support project-based layouts.nd spacing arrangements can be developed for project-based requirements.

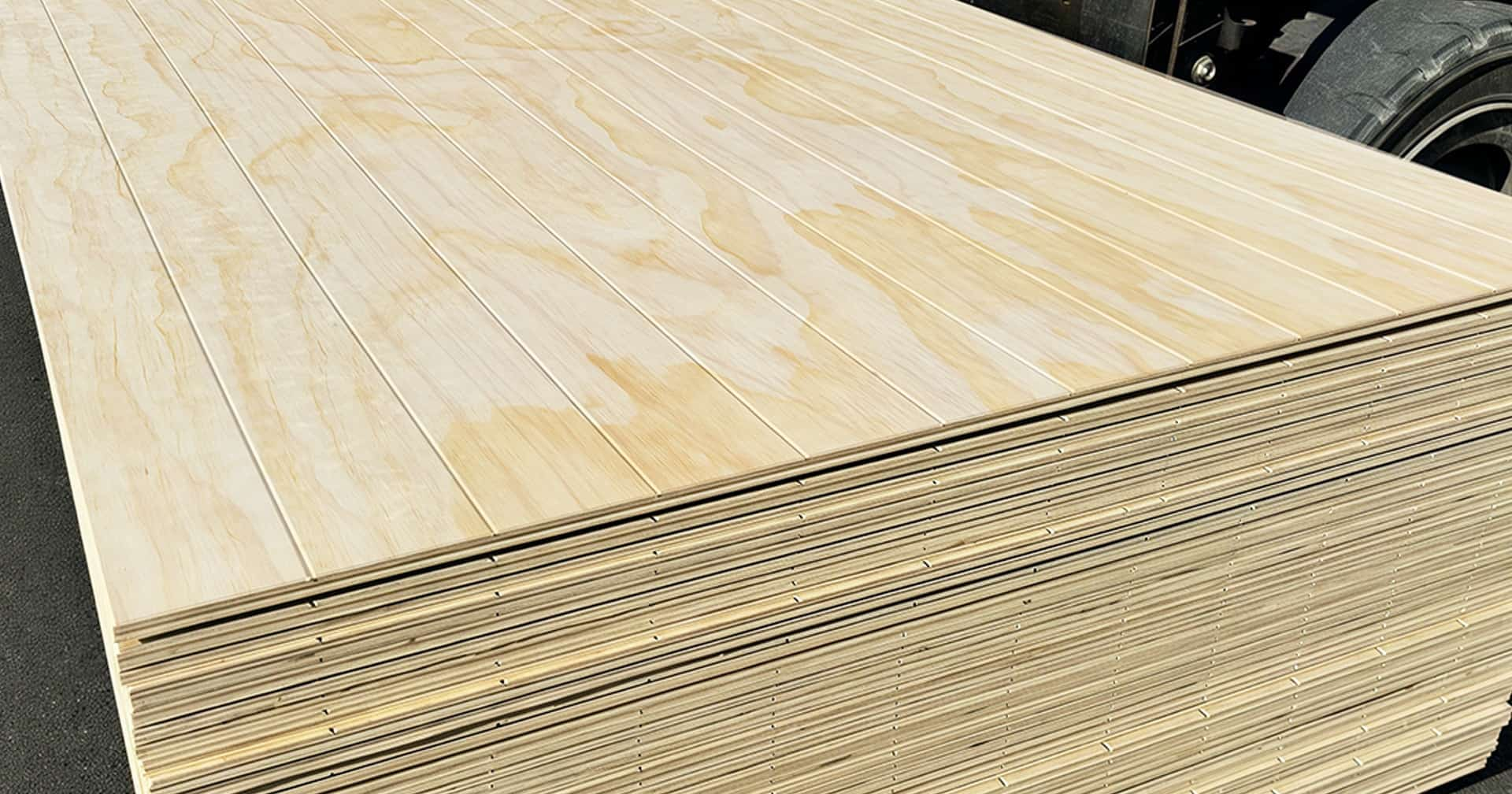

Standard Sizes for Interior Wall Panels

ROCPLY manufactures grooved plywood wall panel in standard sheet sizes suited to interior wall cladding. These sizes align with common wall framing systems, which helps reduce cutting waste and speed up installation. As a result, installers achieve higher efficiency on site.

Custom panel sizes may also be available for project-based requirements, subject to production planning.

ROCPLY Grooved Plywood Wall Panels Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 7 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 9 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 12 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 15 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 17 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 18 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 19 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 25 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

| 28 | 3000/2700/2400 | 1200/1220 | Pine | BDX / CDX |

Technical Specifications

ROCPLY manufactures grooved plywood panels using engineered plywood construction designed for interior environments. Balanced veneer layers support panel flatness and groove accuracy.

Key technical characteristics include:

- Engineered plywood core with controlled lay-up

- Precision-machined groove profiles

- Consistent panel thickness

- Stable bonding for interior performance

Together, these features support reliable installation and long-term durability.

Advantages of Grooved Plywood Wall Panels

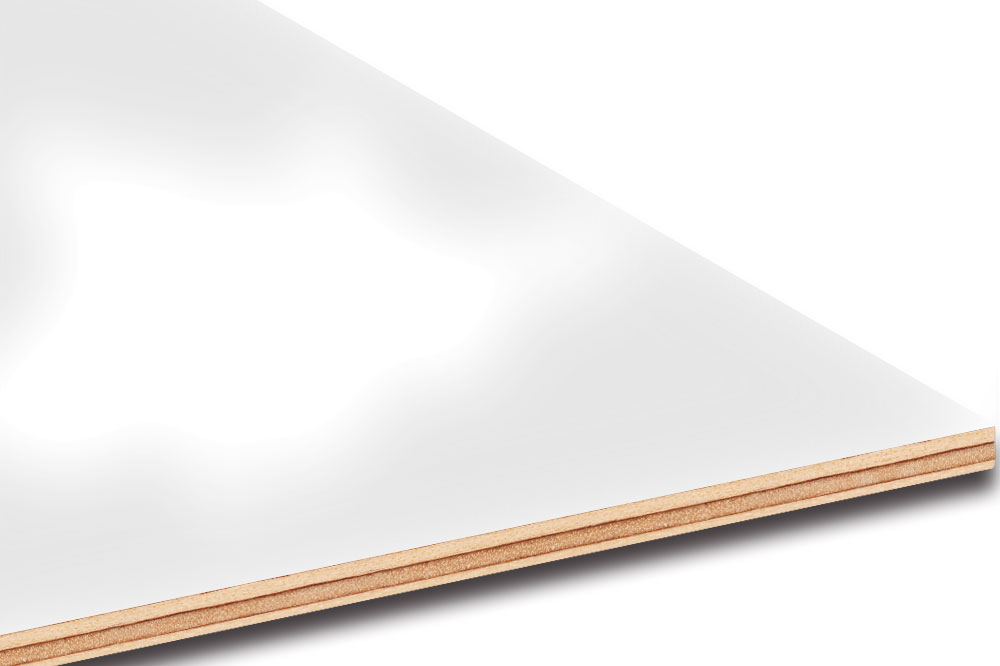

Grooved plywood wall panels offer several advantages compared with flat plywood boards and fiber-based panels.

First, integrated groove profiles eliminate additional surface treatments. Second, plywood provides stronger fixing performance than MDF. Moreover, balanced construction reduces the risk of warping over time. As a result, wall surfaces maintain clean alignment and visual consistency.

Installation and Design Considerations

Installation planning plays an important role when using grooved plywood wall panels. Installers should align groove patterns before fixing panels to maintain continuous visual lines across joints. Because layout planning follows architectural drawings, on-site adjustments remain minimal.

In addition, selecting appropriate groove spacing and orientation helps enhance the overall interior design. Therefore, grooved plywood cladding panels support both efficient installation and refined visual outcomes.

Comparison with Other Wall Panel Systems

Compared with other interior wall panel systems, grooved plywood panels balance appearance and performance effectively. MDF grooved panels may offer smooth surfaces but often lack the fixing strength of plywood. Meanwhile, flat plywood boards provide stability but require extra treatments to achieve textured finishes.

As a result, grooved plywood wall panels combine visual depth and reliable performance in a single interior wall solution.

Certifications and Manufacturing Standards

ROCPLY follows controlled manufacturing processes and responsible timber sourcing practices. Quality management systems support consistent production and stable long-term supply.

For general plywood manufacturing guidance, refer to Standards Australia.

|  |  |  |  |  |

Related Wall Panel Solutions

Grooved plywood wall panels form part of a complete interior wall system. For an overview of related options, you may explore our wall panels category or review project-based solutions through our custom panel wall solutions.

Frequently Asked Questions

Are grooved plywood wall panels suitable for interior use?

Yes. Designers use these panels specifically for interior wall cladding applications.

Can grooved plywood panels be painted or clear finished?

Yes. Panels accept both painted and clear finishes with proper surface preparation.

How do grooved plywood panels differ from V-groove panels?

Grooved panels cover a wider range of groove layouts, while V-groove panels focus on sharp V-shaped profiles.

Are custom groove layouts available?

Yes. Custom groove spacing and panel sizes are available for project-based requirements.