Flooring plywood overview for trade buyers

Floors carry people, stock, and machines. They also set the look of a room. Contractors therefore need panels that align strength and speed. Flooring plywood delivers that mix across many projects. The sheet layout fits common joist centers. It also reduces joints and waste. Crews cut parts with basic tools. You get fast progress and a neat base for finish.

Why ROCPLY flooring plywood stands out

You want steady results day after day. We build panels with tight controls and clear data. Veneer moisture sits in a narrow band. Glue spread stays uniform across the layup. Press time and temperature match the spec. Edges leave the line clean and square. We log every batch for traceability. That discipline protects your schedule and your margin.

Flooring plywood sizes thickness and grades

A standard sheet measures 1220 × 2440 mm. Other sizes are available by plan. Thickness runs from 9 mm to 25 mm for floors. We also supply calibrated sheets for CNC work. Grades cover utility to fine finish. You can mix grades within one order. That approach matches budgets room by room.

Floor plywood strength and subfloor performance

Floors need stiffness under live and static load. We tune major axis strength with smart layup. Cross plies add balance and reduce movement. Tight core control reduces gaps and voids. That choice limits telegraphing under finish. On site, the deck feels solid and quiet. Less bounce means fewer squeaks later.

Flooring plywood vs OSB and MDF

Each sheet class has a role. OSB subfloor offers value in dry frames. It still needs edge care and spacing. MDF gives a smooth paint surface for cabinetry. It suits dry interior zones. Flooring plywood balances grip, stiffness, and repair ease. Screws hold well in veneers. Edges handle traffic during long builds.

Wet or Hot Climates: What to Specify

Moisture and heat test any floor system. Select the right glue class for the job. A-Bond helps in high exposure areas. Edge seal reduces water uptake. Use moisture resistant plywood where humidity stays high. Leave gaps for seasonal movement. Store packs off the slab and under cover. These basics prevent later trouble.

Flooring plywood installation tips for speed

Plan sheet layout before lifting. Stagger joints for strength. Keep fastener length correct for the span. Fix from the center outward to avoid bubbles. Pre-mark joists for quick nailing. Glue lines on joists reduce squeaks. Leave small expansion gaps at walls. Seal cut edges where water may reach.

Commercial projects Flooring plywood

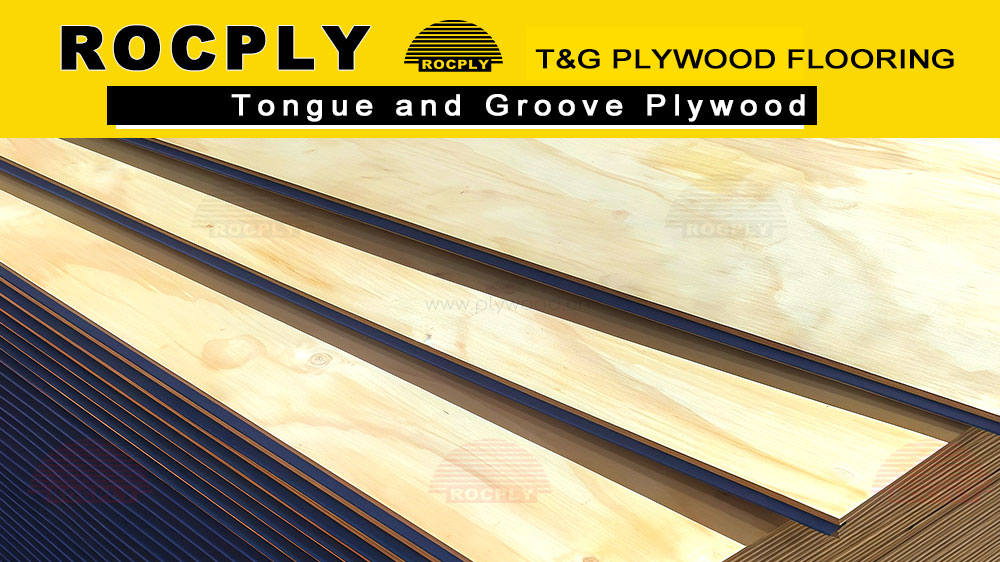

Shops, schools, and clinics need hard working floors. Heavy foot traffic demands high stiffness. We recommend thicker sheets and tighter spans. Tongue and groove plywood helps lock edges. Crews then get smooth transitions under vinyl or tile. Facility teams also gain a floor that resists denting and racking.

Residential builds Flooring plywood

Houses require clean lines and quiet rooms. Use lighter cores for easy handling on upper levels. Match thickness to joist spacing. Plywood underlayment helps under thin finishes. Edges stay tidy at doorways. Families enjoy solid floors with fewer squeaks. Your brand benefits from a better feel.

Flooring plywood underlayment and acoustic comfort

Underlayment refines the surface and the sound. It supports vinyl, laminate, and engineered wood. Choose calibrated sheets for seamless joins. Gaps and steps then stay minimal. Add acoustic layers where noise control matters. The system works together as a calm base for living or work.

Sustainability and traceable sourcing

Buyers ask for proof on timber origin. We maintain clear chains of custody. Mills record species and harvest regions. Third-party audits review paperwork and practice. Packs carry scannable labels for quick checks. Your compliance team receives tidy files. That clarity helps you bid with confidence.

Quality control you can audit

We test bond strength and thickness on set schedules. Press logs record temperature and time. Operators check edge square and surface flatness. Non-conforming sheets leave the stream. Batches ship with codes and dates. You can track feedback to the exact run. Problems get fixed, not ignored.

Packaging logistics and damage reduction

Transit can harm edges and corners. We protect sheets with PET straps and guards. Pallets offer forklift access from both sides. Waterproof labels survive long routes. Barcodes speed intake at your warehouse. Container plans balance weight and space. The load arrives ready for work.

People also ask about flooring plywood

What thickness works best for subfloors?

Common spans use 18 mm or 21 mm. Tight centers can use 15 mm. Heavy loads may need thicker sheets.

Is plywood underlayment required?

Use underlayment under thin finishes. It smooths joints and gives cleaner seams.

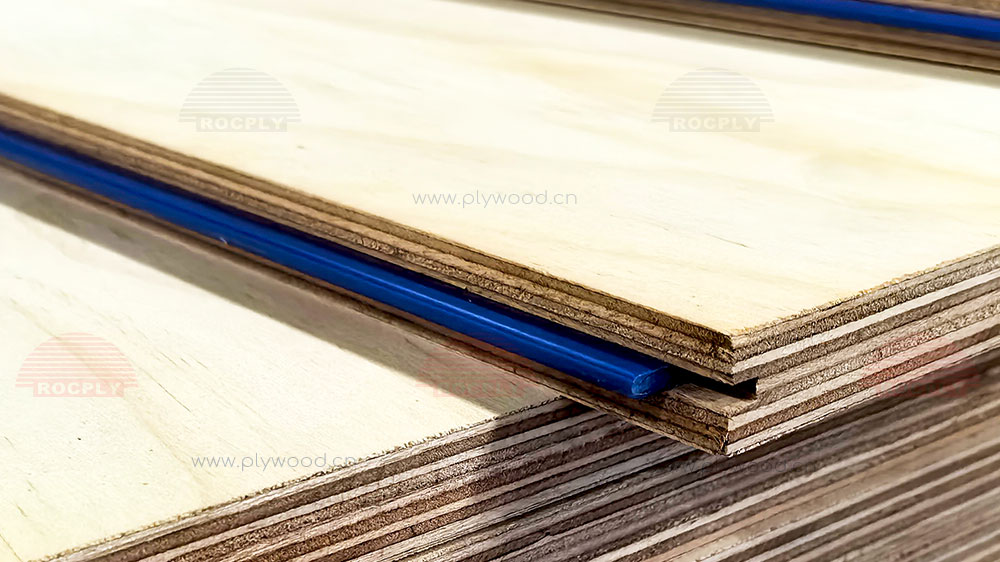

Tongue and groove plywood or square edge?

T&G locks edges and reduces steps. Square edge works with blocking between joists.

Can plywood replace OSB subfloor?

Yes, when the spec allows. Plywood offers strong screw grip and quick repairs.

How do I prevent squeaks?

Use glue on joists and correct nail patterns. Fix sheets while the frame stays dry.

Is moisture resistant plywood necessary?

Select it for damp zones. Edge seal and airflow help a lot.

Flooring plywood cost value and savings

Price is one part of the story. Time on site costs more across weeks. Panels that install fast save labor. Fewer callbacks save even more. Durable floors need fewer repairs. Logistics also matter. Compact packs load and unload faster. Your total cost per square meter then drops.

Common mistakes and quick fixes

Dragging sheets across concrete chips edges. Use bearers and lift cleanly. Tight butt joints cause peaking. Leave small gaps as per spec. Wrong fastener length weakens hold. Match length to thickness and span. Wet storage leads to warp. Keep packs dry with air space below. These fixes are simple and proven.

Specifications checklist for buyers

Confirm size and thickness for each zone. Set the glue class for exposure. Choose grade for visible or hidden areas. Decide on tongue and groove plywood where spans are wide. Define edge seal color if needed. Share pallet counts and weight limits. Ask for barcode formats that match your system. Align delivery dates with site access windows.

Work with ROCPLY today

Tell us your scope and schedule. We will map a floor package that fits. ROCPLY flooring plywood arrives on time and ready. Your crews install faster with fewer surprises. You hand over solid floors that stay quiet and true. Our team supports you from quote to final delivery.

How ROCPLY solves common pain points

Flatness and fit. We sand to tight tolerances for smooth finishes. Panels sit flush at joints. Installers move faster with less prep.

Strength with control. Layups target stiffness along the major axis. Floors feel firm under load. Long spans remain within deflection limits.

Moisture management. Edge seals reduce uptake at cuts. Correct glue class resists cycles. Storage guides keep packs in shape.

Sound and comfort. Underlayment options cut noise. Calibrated sheets make clean seams. Rooms feel calm and refined.

Supply reliability. Forecasts and safety stock reduce gaps. Labels and data simplify intake. You keep projects moving.

Where related keywords fit your plan

Subfloor plywood supports live loads across joists. Plywood underlayment smooths thin coverings. Tongue and groove plywood reduces steps at panel joins. Structural plywood serves high demand areas. Moisture resistant plywood helps in humid rooms. OSB subfloor still suits dry frames with correct detailing.

Ordering made simple

Share drawings and span tables if possible. We confirm thickness and grade by room. Pallet plans match your forklifts and aisles. Mixed loads are available by layer. You receive clean documents and tracking. The process feels clear from start to finish.

Final brand note

ROCPLY flooring plywood backs your reputation. Strong panels, tidy packs, and steady support keep work flowing. Ask for samples, data sheets, and a quote today.

Tongue and Groove Plywood

Tongue and Groove OSB Flooring

Tongue and Groove Particle Board Flooring

Post time: Oct-13-2025