Custom Grooved Plywood Wall Panels

Custom Grooved Plywood Wall Panels for Project-Based Interior Design

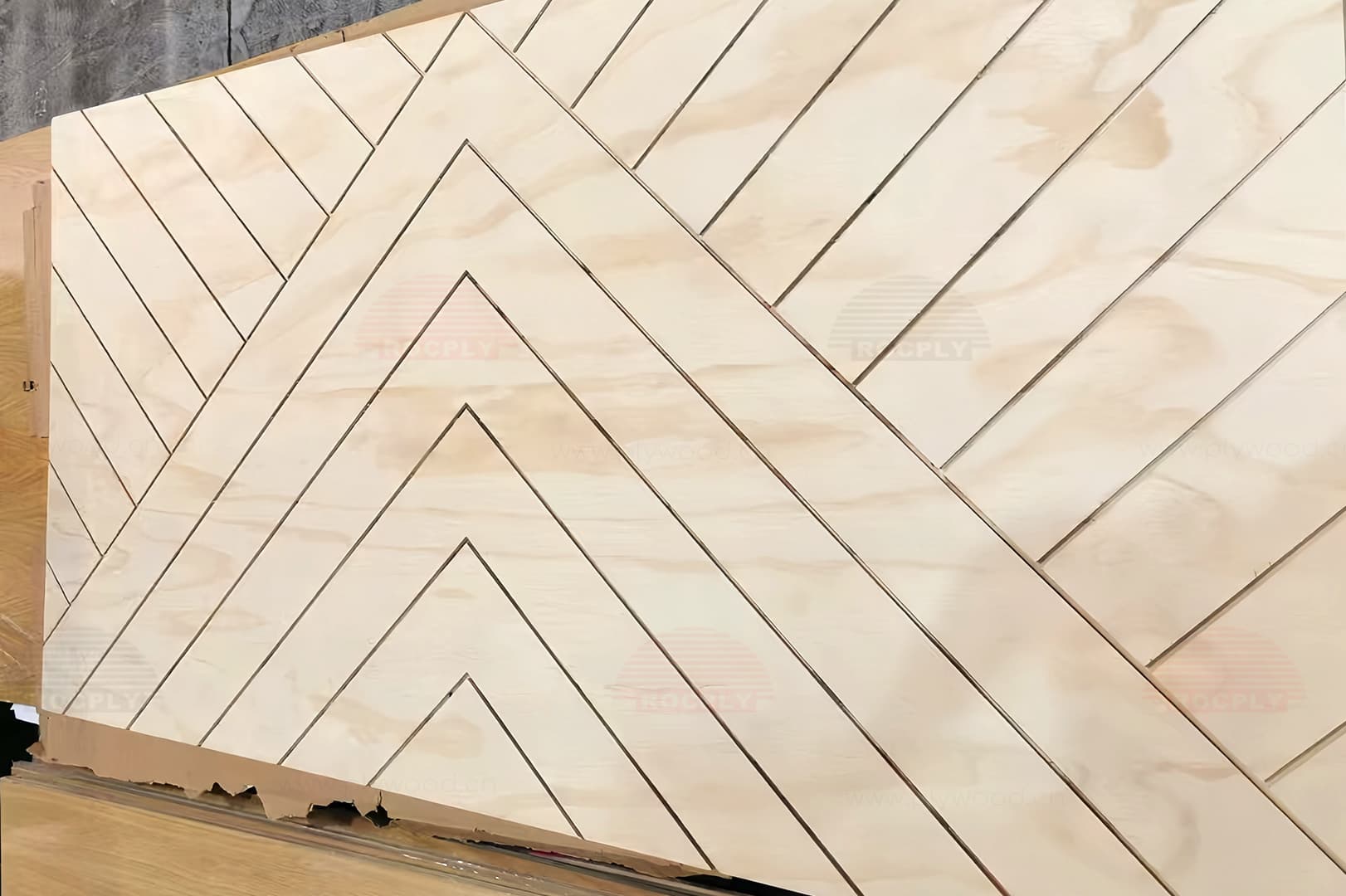

Custom grooved plywood wall panels allow architects, designers, and builders to create interior walls that match specific project requirements. Instead of working within fixed groove layouts, custom panels offer flexible spacing, depth, and panel proportions. As a result, interior wall designs can align more precisely with lighting plans, furniture layouts, and architectural lines.

ROCPLY develops custom grooved plywood wall panels for residential, commercial, and large-scale interior projects. By controlling both panel structure and groove machining, we help project teams achieve consistent visual outcomes while maintaining reliable plywood performance.

Why Choose Custom Grooved Plywood Panels?

Standard wall panels work well for many interiors. However, complex projects often demand more control. Custom grooved plywood panels address this need by allowing tailored groove patterns that support both design intent and construction efficiency.

In addition, custom panels reduce on-site modifications. When groove spacing and panel sizing match the design drawings, installation becomes faster and more predictable. Therefore, project timelines stay under control while finishing quality improves.

Custom Groove Patterns and Layout Options

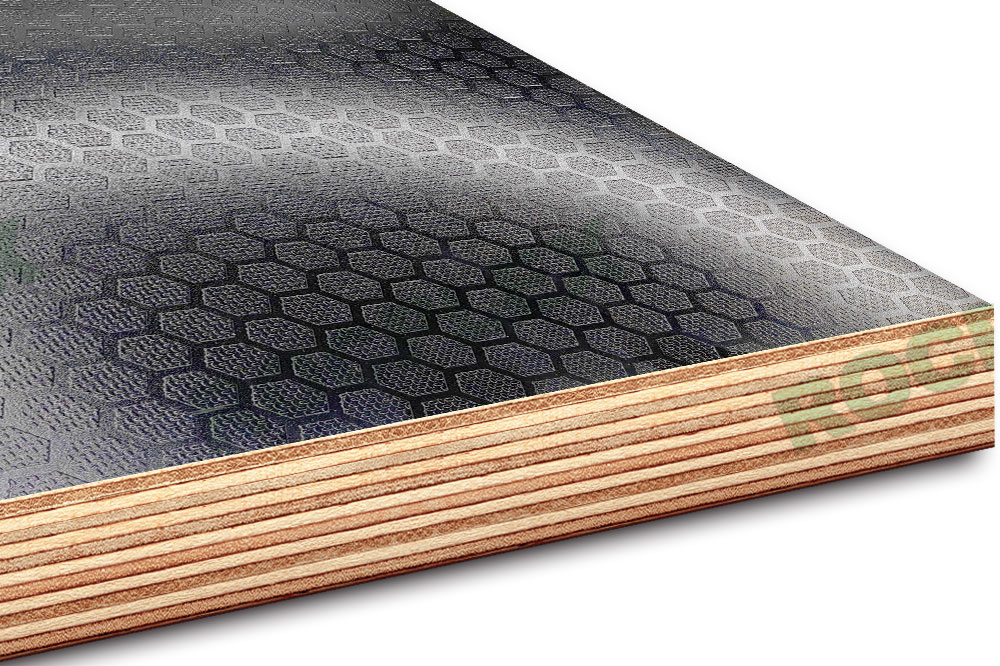

Custom grooved plywood wall panels can be produced with a wide range of groove configurations. Designers may adjust groove spacing, depth, and alignment to suit different interior concepts.

Typical customization options include:

- Narrow or wide groove spacing

- Uniform or varied groove rhythms

- Adjusted groove depth for shadow control

- Panel sizing matched to wall modules

For projects that follow standard layouts, you may also review our Grooved Plywood Wall Panels to compare fixed and custom solutions.

Grooved Panel Series

Applications for Custom Grooved Plywood Wall Panels

Commercial and Public Spaces

Custom grooved panels are widely used in offices, hotels, retail spaces, and public interiors. Designers often specify custom layouts to guide movement, frame key areas, or reinforce brand identity. As a result, wall surfaces become part of the overall spatial experience rather than simple finishes.

Residential and High-End Interiors

In premium residential projects, custom panels help create feature walls with controlled proportions and clean detailing. Homeowners benefit from unique interior expressions while maintaining the natural warmth of plywood surfaces.

Project-Based Interior Fit-Outs

Large interior fit-outs often require repeated panel dimensions across multiple spaces. Custom grooved plywood panels ensure consistent results across all areas. Therefore, builders can maintain installation efficiency while meeting strict visual requirements.

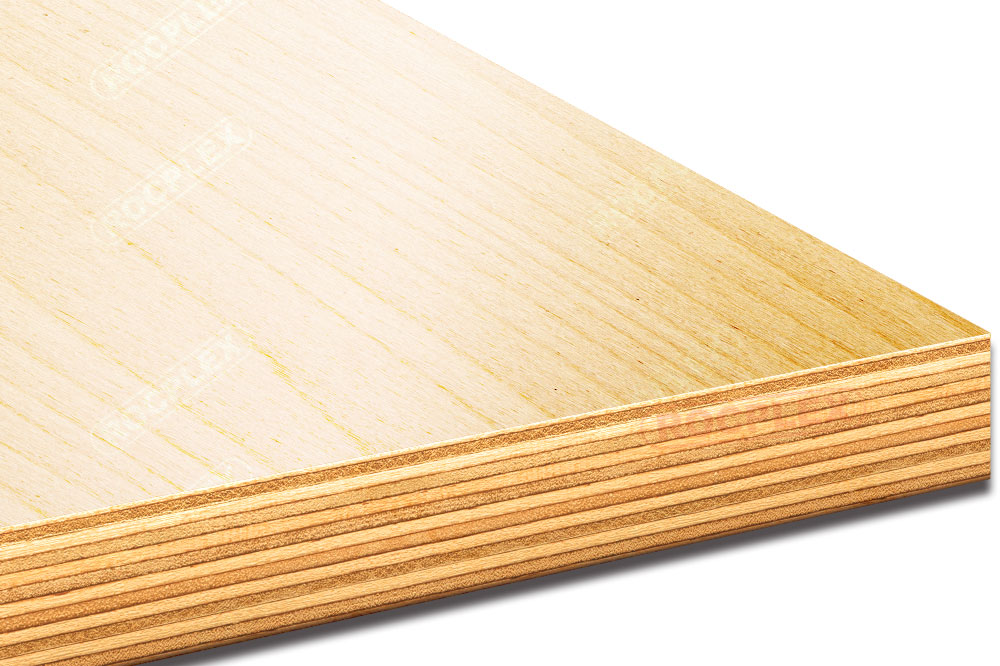

Panel Construction and Material Performance

ROCPLY custom grooved plywood wall panels use stable plywood cores designed for interior environments. Consistent veneer layering supports precise groove machining and reliable panel flatness. In addition, controlled moisture content helps panels perform well in indoor conditions.

Because ROCPLY manages production internally, panel quality remains consistent across project batches. This consistency helps reduce variation during installation and finishing stages.

Custom Sizes, Thicknesses, and Finishes

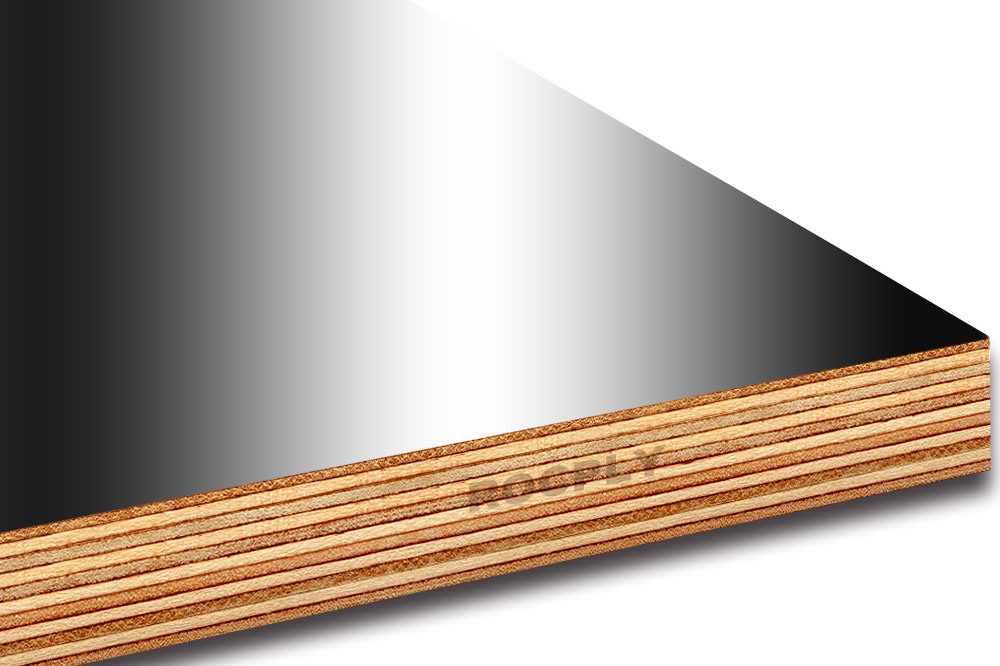

Custom grooved plywood wall panels can be supplied in sizes and thicknesses suited to project specifications. Panels may also be prepared for different surface finishes depending on design intent.

Common finish options include:

- Paint-ready surfaces

- Clear finishes that highlight wood grain

- Pre-finished options for faster installation

For decorative interior solutions with fixed groove layouts, you may also explore our plywood wall panel systems to review standard options.

From Design Concept to Production

ROCPLY supports custom panel projects from early design stages through to production. Project teams can discuss groove layouts, panel sizing, and performance requirements before finalizing specifications. As a result, production aligns closely with project drawings and installation plans.

This collaborative approach reduces design changes during construction. Therefore, project risks stay low and installation quality remains high.

Related Grooved Wall Panel Solutions

Custom grooved plywood panels form part of a complete interior wall solution range. Depending on project scope, you may also compare:

- Grooved Plywood Wall Panels for standard layouts

- Decorative Grooved Plywood Panels for visual design emphasis

Together, these options allow designers and builders to select the most suitable solution for each project zone.

Design Flexibility and Project Coordination

Custom grooved plywood wall panels also support smoother coordination between design and construction teams. Because groove layouts and panel sizes follow project drawings, designers can reduce on-site adjustments. As a result, installers work with clearer references and fewer changes during installation. In addition, this alignment helps maintain consistent visual results across different areas of the same project, especially in large interior fit-outs.

Frequently Asked Questions

When should I choose custom grooved plywood panels?

Custom panels are ideal when standard groove spacing does not meet design or layout requirements. They suit project-based interiors with specific visual goals.

Are custom grooved panels suitable for interior use only?

Yes. Custom grooved plywood wall panels are intended for interior wall applications in controlled environments.

Can custom groove layouts match architectural drawings?

Yes. ROCPLY develops groove spacing and panel sizes based on project drawings and design intent.

How do custom panels affect installation time?

Custom panels often reduce on-site adjustments. As a result, installation becomes faster and more predictable.

Certification and Quality Control

ROCPLY follows controlled manufacturing and responsible timber sourcing practices. Quality management systems support consistent panel production and stable long-term supply.

Certification documentation can be provided when required to support project specifications.

|  |  |  |  |  |

For general plywood manufacturing and application guidance, refer to the Australian standard AS/NZS 2269 published by Standards Australia.

.

Start Your Custom Wall Panel Project

If your project requires precise groove layouts, consistent panel quality, and reliable interior performance, custom grooved plywood wall panels offer a practical solution. Contact ROCPLY to discuss your design concept, panel requirements, and production timeline.