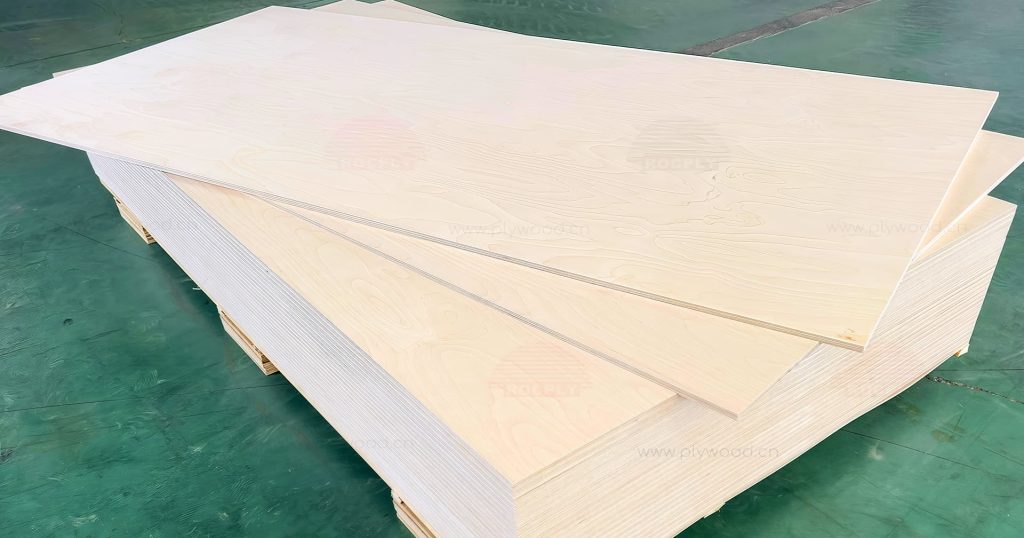

MR Plywood: Moisture-Resistant Plywood for Interior Fit-Outs

MR plywood is designed for interiors where humidity changes, but where water does not stay on the panel for long. Therefore, it is widely used for furniture, joinery, and fit-outs. In this guide, you will learn what MR grade plywood means, how it compares with exterior panels, and what to confirm before you buy.

What is MR plywood (and what it is not)

MR stands for moisture resistant. However, MR plywood is not waterproof. It performs well in normal indoor conditions, such as bedrooms, offices, and most furniture workshops. On the other hand, if your project faces rain, frequent wet cleaning, or standing water, you should select an exterior-grade panel instead.

MR ply applications for furniture and joinery

MR plywood is a practical choice when you need stable interior sheets with good workability. For example, it is commonly used for:

- kitchen and wardrobe carcasses (avoid direct sink splash zones unless sealed well)

- bedroom furniture, shelving, drawers, and partitions

- shopfitting, display units, and interior wall linings in dry areas

- interior doors (as specified by your door design)

- packaging and crating where weather exposure is not expected

Meanwhile, avoid MR grade plywood in exterior structures, balconies, wet bathrooms, and any location where edges remain wet for hours.

MR grade plywood glue types (UF vs MUF)

Glue type often decides real-life performance. In many markets, MR ply uses UF (urea-formaldehyde) bonding for interior use. In addition, some suppliers offer MUF (melamine-urea) systems or reinforced resins for improved stability in higher-humidity interiors. As a result, two panels sold as “MR” can behave differently on site.

When comparing quotations, confirm these items in plain terms:

- Adhesive system (UF or MUF) and intended service conditions

- Moisture content at packing

- Edge sealing recommendation for your application

UF bonded plywood vs exterior plywood: how to choose

Choose MR plywood when the job is mainly interior. However, if the panel will face repeated wetting, upgrade to an exterior solution. For example, film faced plywood is built for concrete formwork and wet-site cycling, while UF bonded plywood targets interior furniture. Therefore, matching the panel grade to the service environment reduces claims and rework.

MR plywood specifications to confirm before ordering

To reduce complaints, lock these specs into your PO. In addition, request production photos and samples from the same line.

- Thickness and tolerance (and whether the panel is calibrated/sanded)

- Face/back grade rules (repairs, knots, and color limits)

- Core construction and gap control (important for screw holding)

- Bond quality target (and test method if available)

- Emission target for your market and customer segment

- Packing method (corner protection, pallet base, wrapping, straps)

Buying checklist for moisture resistant plywood

Use this quick checklist to screen suppliers. Then, confirm consistency with pre-shipment samples.

- Flatness after storage and transport

- Clean sanding and predictable face appearance

- Core gap control on cut edges

- Traceability by batch or production date

- Clear claim for interior use and handling guidance

How to improve UF bonded plywood performance on site

Even good interior grade plywood can fail if the site method is poor. Therefore, apply these steps to reduce swelling and edge issues:

- Seal cut edges before installation, especially for cabinets

- Store sheets off the slab and away from wet trades

- Allow acclimation in the room before final fixing

- Use the correct fasteners and pilot holes to prevent splits

- Improve ventilation in kitchens and laundries to reduce moisture swings

FAQ: MR plywood

Is MR plywood waterproof?

No. It is moisture resistant for interior use, not for standing water or outdoor exposure.

Can I use UF bonded plywood for kitchen cabinets?

Yes for most cabinet carcasses. However, seal edges and protect panels near sinks and dishwashers.

What thickness is common for furniture?

Many builds use 15–18 mm for carcasses and shelves, with thinner panels for backs and partitions.

How do I avoid edge swelling?

Edge sealing, correct storage, and controlled site moisture are the biggest factors.

What should I ask a supplier before I buy?

Confirm glue type, core species, tolerance, face rules, emission target, packing, and request a batch sample.

Build a Reliable MR Plywood Supply Line

Confirm batch traceability, packing standard, and a clear grading rule for every shipment. This makes it easier to scale distribution without quality disputes.

Plywood

ROCPLY, a trusted name in the construction materials market, is proud to announce the launch of their new line of high-quality ply wood solutions. Designed to meet the diverse needs of the industry, ROCPLY now offers an extensive range of ply options, including structural, birch, marine, and MR plywood.

ROCPLY Plywood Superior Quality and Durability:

ROCPLY ply solutions are meticulously crafted to deliver superior quality and durability. The structural ply offers exceptional strength and stability, making it ideal for applications that require reliable load-bearing capabilities. Birch ply wood, known for its fine grain and consistent thickness, provides versatility and aesthetic appeal. The marine ply wood is specially treated to withstand moisture and weather conditions, making it perfect for marine and outdoor projects. Lastly, the MR ply wood offers moisture resistance, making it suitable for interior applications where protection against humidity is essential.

ROCPLY Plywood Wide Range of Applications:

ROCPLY ply wood products cater to various industries and applications. The structural ply is widely used in commercial and residential construction projects, including flooring, roofing, and formwork. Birch plywood is sought after by architects and designers for its versatility in furniture making, cabinetry, and interior fittings. Marine plywood is a top choice for boat building, docks, and other water-related structures due to its water-resistant properties. MR plywood finds applications in indoor furniture, cabinets, and decorative purposes, offering both functionality and style.

ROCPLY Plywood Commitment to Quality and Sustainability:

ROCPLY is committed to delivering ply wood solutions that not only meet high-quality standards but also adhere to sustainable practices. Their ply is sourced from responsibly managed forests, ensuring a minimal impact on the environment. With ROCPLY’s plywood options, builders and architects can confidently create sustainable and eco-friendly structures without compromising on performance.

We are thrilled to introduce our new line of ply wood solutions. At ROCPLY, we strive to provide our customers with the finest quality materials that meet their specific requirements. With our range of structural, birch, marine, and MR plywood, we aim to empower builders, architects, and craftsmen to bring their visions to life.

For more information about ROCPLY’s plywood solutions and to request samples, please visit [website] or contact [contact details].

About ROCPLY Plywood:

ROCPLY is a leading brand in the construction materials industry, known for delivering high-quality products to wholesalers, builders, and contractors. With a commitment to innovation, sustainability, and customer satisfaction, ROCPLY offers a wide range of construction timber material.

Post time: Jan-12-2026