Bracing Wooden Wall Panels In Modern Building

Frames carry more service loads today. Roofs span further and walls run longer, making the use of wooden wall panels an attractive option for construction. At the same time, owners want lighter structures and open living zones. Codes also set strict rules for racking resistance.

Bracing wooden wall panels answer all of these demands. They stiffen the frame and still look neat in the finished space. Instead of adding thin straps and then lining, teams can often install one panel layer.

This simple approach reduces products on site. It also helps planners keep details tidy across many jobs. ROCPLY wood wall panels support this idea with stable cores and consistent faces.

How Bracing Wooden Wall Panels Work In A Frame

Every framed wall needs a clear path for side loads. Wind and quake forces push the top of the wall sideways. Without bracing, joints open and the frame leans.

Bracing wooden wall panels form a flat brace across the studs. Each fastener shares part of the load. Together, sheet and fixings act like a wide diagonal brace.

Engineers classify these sheets as structural wall panels. They use test data to set bracing units for each wall length. When builders follow the fixing pattern, the wall meets the design rating.

Turning A Loose Frame Into A Rigid Box

A bare frame feels light and flexible. When someone pushes on a corner, the wall moves. Once bracing sheets go on, the wall stiffens.

Bracing wooden wall panels turn the open frame into a rigid box. Corners stay square under wind or live loads. Doors and windows also stay aligned for longer.

This rigid box effect protects linings, tiles and cladding. Cracks reduce and callbacks drop. That benefit supports both builders and wholesalers.

Nails, Screws And Structural Wall Panels

Fixings matter as much as the panel itself. Designers set nail or screw size and spacing. Edges need closer centres than the field.

When teams follow these details, structural wall panels work as planned. If they skip fasteners, the wall loses capacity. Good site checks keep quality up.

ROCPLY provides clear fixing charts with each range. Crews can see the pattern in one glance. This support helps keep performance consistent across sites.

Bracing Wooden Wall Panels Versus Plain Lining Boards

Plain lining sheets exist to finish a room. They hide services and create a paint ready surface. However, they often lack the strength to act as bracing.

Bracing wooden wall panels add stiffness as well as finish. One panel can satisfy both tasks in suitable walls. That reduces layers and speeds up the program.

Strength And Compliance

Compliance drives many design choices. Councils and certifiers want clear documentation. They also want simple details that crews can build correctly.

Bracing wooden wall panels come with known structural values. Designers can show these values in their bracing design. Inspectors can then match what they see on site with the drawings.

Plain linings seldom offer this clarity. They may need extra straps or proprietary bracing systems. Those extra parts add cost and complexity.

Finish Quality And Design Flexibility

Finish quality still matters to owners. They judge walls by what they see and feel. Panels need to accept paint, stain or clear coats cleanly.

Bracing wooden wall panels start with good timber faces. Light sanding and filling give a smooth base. After that, painters can follow their normal system.

Designers can also mix these panels with other wood wall panels. Feature walls, reveals and niches can all share the same tone. The result feels calm and unified.

Comparing Bracing Wooden Wall Panels With Other Solutions

There are many ways to brace a frame. Each method has its place. However, not all options give both strength and a finished surface.

Straps, Rods And Cross Bracing

Metal straps run diagonally across studs. They work well in narrow walls and service areas. Yet they still need a lining over the top.

Steel rods and frames can brace larger bays. They suit some commercial jobs and high load zones. Once again, they require a separate interior lining.

Bracing wooden wall panels often replace these items in light framed homes. They reduce parts and steps while still meeting design loads.

Sheet Bracing In Fibre Cement Or OSB

Fibre cement sheets and OSB boards also serve as bracing. They usually sit on the exterior face of the frame. Cladding then covers them.

These panels can be strong. However, they may not offer the warm look many owners want inside. Timber wall panels feel better in living rooms and bedrooms.

In some projects, designers mix systems. Fibre cement bracing goes outside. Inside, bracing wooden wall panels appear where extra strength is useful.

Mixed Systems With Wood Wall Panels

Full timber interiors do not suit every room. Wet zones, garages and plant areas might use other linings. In those spaces, plain boards can work fine.

In feature spaces, wood wall panels shine. Designers often choose bracing wooden wall panels for main walls. They then use other interior wall panels for lighter partitions.

This mix lets builders balance cost, strength and style. ROCPLY ranges support this with matching tones across different panel types.

Materials Used In Bracing Panel Systems

The core material decides how a panel behaves. Density, bond and veneer layout all play key roles.

Plywood Wall Panels For Structural Bracing

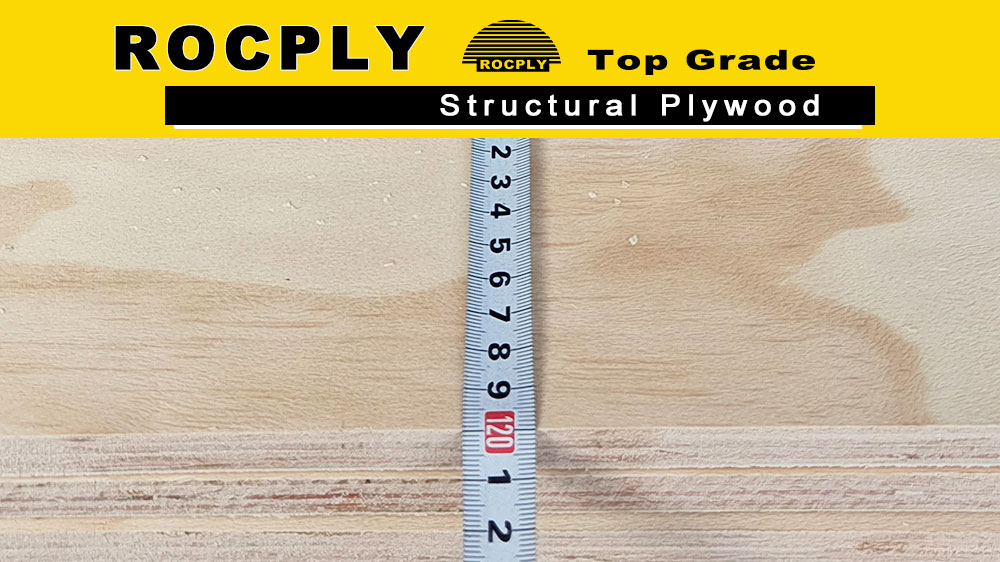

Plywood wall panels remain a clear favourite for bracing. Cross laid veneers share load and limit movement. Edges stay firm under nails and screws.

Grading systems set bond quality and face class. This means designers can trust that each sheet meets the label. That trust feeds into safe and durable buildings.

ROCPLY uses strict veneer selection for bracing products. Glue lines and pressing cycles follow tight controls. These steps help every sheet behave predictably.

Timber Wall Panels And Wooden Wall Panelling

Not every timber panel carries bracing loads. Many products exist only as decorative wooden wall panelling. They focus on pattern, colour and profile.

These panels still have value. They lift the mood of many rooms. They also pair well with bracing layers behind them.

Bracing wooden wall panels sit at the structural end of this family. They share the warm face of timber wall panels. Yet they also deliver measurable stiffness and strength.

Moisture, Durability And Site Conditions

Moisture control makes or breaks panel performance. Even good products can fail if they sit in the wrong conditions.

Keeping Panels Dry Before Install

Packs should rest clear of the ground. Cover them, yet leave room for air flow. This prevents condensation under plastic.

Before fixing, crews should check moisture content. Too wet or too dry sheets may move after installation. Simple meters help avoid this risk.

Bracing wooden wall panels from ROCPLY ship in export ready packs. Labels show grade and handling notes. Following those notes protects long term results.

Bracing Panels In Wet Or Coastal Zones

Some walls sit in harsher climates. Coastal wind, driving rain and salt spray test every joint. In such places, detailing matters even more.

Wraps, flashings and cavity systems keep bracing wooden wall panels dry. Edges should never sit in standing water. Claddings also need correct clearances.

When trades follow these rules, plywood based panels last for many years. Frames stay stiff and interiors stay sound. Owners enjoy solid homes rather than creaking shells.

Installation Workflow With Bracing Wooden Wall Panels

Simple workflow helps crews stay on time. Straightforward steps limit errors and waste.

Planning Layouts And Openings

Teams start with set out. They mark stud spacing, openings and bracing lines. Planning reduces small cuts and awkward joins.

Bracing wooden wall panels should cover full bays where possible. Joints should land on studs or blocking. This keeps strength continuous.

Openings for windows and doors need careful trimming. Offcuts can often brace short return walls. That keeps waste low.

Fixing Patterns That Inspectors Trust

Inspectors look for neat, consistent fixing. They expect edge and field spacing to match the plans. Random nails raise questions.

Bracing wooden wall panels need the right fastener type and length. Heads should sit flush, not sunk deep. This protects both holding power and finish.

ROCPLY guidance sheets show patterns clearly. Crews can pin them near the saw bench or on the wall. This keeps everyone aligned through the job.

Working Around Services And Retrofits

Services can cut through bracing if teams are not careful. Large holes near corners weaken the wall.

Before drilling, electricians and plumbers should check with the foreman. Alternatives may exist, such as running lines in ceiling spaces.

In retrofits, some walls gain new loads. Adding bracing wooden wall panels on the room side can help. Designers can review the frame and specify new panel lengths.

Comfort, Acoustics And Everyday Performance

Bracing alone is not the full story. People live and work in these spaces every day. Feel and sound matter.

Solid Feel Under Everyday Loads

A stiff wall feels different to the touch. Doors close cleanly and latches align. Pictures stay straight over long periods.

Bracing wooden wall panels support this solid feel. They reduce flex and twist in the frame. Floors and ceilings also benefit from this stability.

Over time, owners notice fewer cracks. They hear fewer creaks during wind or foot traffic. This calm background supports a better living experience.

Acoustic Gains From Wood Based Walls

Hard, bare surfaces bounce sound. In contrast, timber faces break it up. Grain and micro texture scatter echoes.

When designers combine bracing wooden wall panels with soft furnishings, rooms become much quieter. Speech stays clear without harsh reflection.

In offices and schools, this supports focus. In homes, it supports rest. Quiet comfort becomes part of the product story you sell.

Cost, Value And Stock Planning For Wholesalers

Wholesalers think in terms of turn, margin and risk. Products must move and not cause trouble.

One Panel For Many Wall Roles

A panel that can brace and line walls reduces range clutter. Bracing wooden wall panels fit this role. They suit external frames, feature walls and some service areas.

Dealers can therefore hold fewer SKUs. Packs stack neatly and labels stay clear. Staff learn one story and tell it well.

This focus supports higher turns and better stock control. It also reduces the risk of slow moving odd items.

How ROCPLY Supports Reliable Supply

ROCPLY builds bracing products around stable plywood cores. Plants follow strict checks on bond, moisture and thickness.

Clear branding and documents support compliance checks. Engineers can sign off walls with confidence. Builders then trust repeat orders from the same line.

As a result, bracing wooden wall panels become a default choice for many customers. Your yard becomes the simple, safe source for these needs.

Planning Your Next Project With Bracing Wooden Wall Panels

Future projects will keep pushing for lighter, stronger and faster builds. Frames must brace well and still feel pleasant to live in.

Bracing wooden wall panels answer this brief with one clear product group. They combine structure, comfort and style in a familiar sheet format.

When you stock ROCPLY wood wall panels, you back that promise with proven cores and consistent faces. Builders get panels they enjoy using. Owners get walls that stay solid and calm.

That is the kind of product that earns its place in every container and every quote list.

Plywood

ROCPLY, a trusted name in the construction materials market, is proud to announce the launch of their new line of high-quality ply wood solutions. Designed to meet the diverse needs of the industry, ROCPLY now offers an extensive range of ply options, including structural, birch, marine, and MR plywood.

ROCPLY Plywood Superior Quality and Durability:

ROCPLY ply solutions are meticulously crafted to deliver superior quality and durability. The structural ply offers exceptional strength and stability, making it ideal for applications that require reliable load-bearing capabilities. Birch ply wood, known for its fine grain and consistent thickness, provides versatility and aesthetic appeal. The marine ply wood is specially treated to withstand moisture and weather conditions, making it perfect for marine and outdoor projects. Lastly, the MR ply wood offers moisture resistance, making it suitable for interior applications where protection against humidity is essential.

ROCPLY Plywood Wide Range of Applications:

ROCPLY ply wood products cater to various industries and applications. The structural ply is widely used in commercial and residential construction projects, including flooring, roofing, and formwork. Birch plywood is sought after by architects and designers for its versatility in furniture making, cabinetry, and interior fittings. Marine plywood is a top choice for boat building, docks, and other water-related structures due to its water-resistant properties. MR plywood finds applications in indoor furniture, cabinets, and decorative purposes, offering both functionality and style.

ROCPLY Plywood Commitment to Quality and Sustainability:

ROCPLY is committed to delivering ply wood solutions that not only meet high-quality standards but also adhere to sustainable practices. Their ply is sourced from responsibly managed forests, ensuring a minimal impact on the environment. With ROCPLY’s plywood options, builders and architects can confidently create sustainable and eco-friendly structures without compromising on performance.

We are thrilled to introduce our new line of ply wood solutions. At ROCPLY, we strive to provide our customers with the finest quality materials that meet their specific requirements. With our range of structural, birch, marine, and MR plywood, we aim to empower builders, architects, and craftsmen to bring their visions to life.

For more information about ROCPLY’s plywood solutions and to request samples, please visit [website] or contact [contact details].

About ROCPLY Plywood:

ROCPLY is a leading brand in the construction materials industry, known for delivering high-quality products to wholesalers, builders, and contractors. With a commitment to innovation, sustainability, and customer satisfaction, ROCPLY offers a wide range of construction timber material.

Post time: Jan-05-2026